10

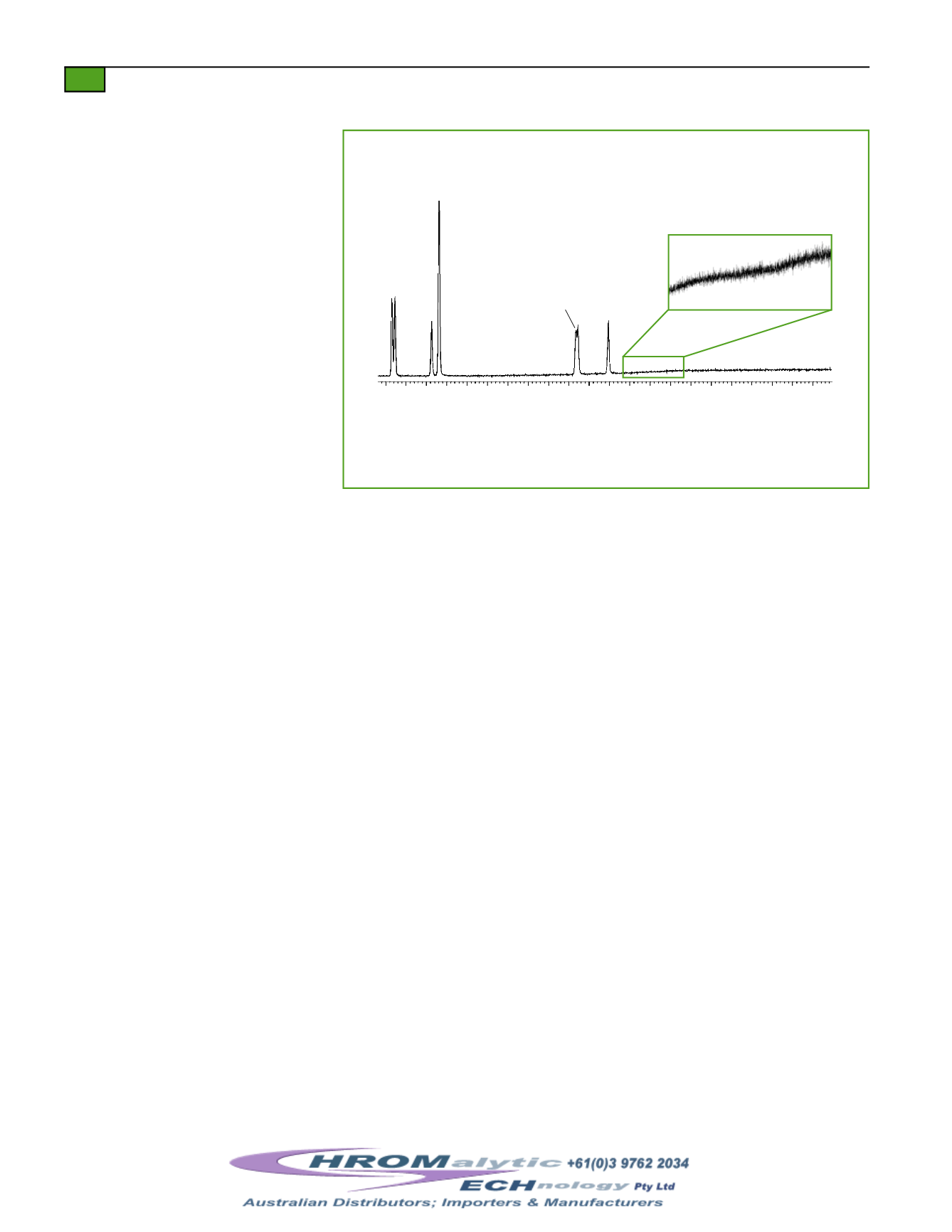

Figure3.

TheRtx

®

-5SilMS column exhibits lowbleed at 20ng concentration level.

Detector saturationalsocanbecausedby theconcentrationof theanalytes. Itwas common

practiceonolder, less sensitiveGC/MS systems to increase themultiplier voltageabove the tune

value to improve sensitivityof low-concentration standards.This techniquecan lead toproblems

with thenewer,more sensitive instruments. It ismuchmore likely thehigher concentration

calibration standardswill saturate thenewGC/MS systems. Itmaybenecessary to reduce the

multiplier voltagebelow the tunevalue if high-end roll-off isobserved.High-end roll-off also

maybeobservedwhenusingpressure-pulsing injection techniques tominimizehighmolecular

weight discrimination. If this isobserved, youmayeither increase the stationaryphase film

thickness, or increase thecolumndiameter.Alternatively, youmaymodify the injection

conditions toeliminate the sourceof theoverload.

Columncapacity

alsomust beaddressedwhenoptimizing theanalysis.The typical calibration

range formanyof thesemethods is20 to160ngper compound.This requires acolumn stationary

phaseanddiameter thatwill not overloadwitha160ngor larger injection.Because there is a loss

of analyte inany splitless injection, calculationof thenecessarycolumncapacity isnot simple. If

the injectionhasbeenoptimized for splitlesshold-timeand fused silicawool isbeingused in the

liner tominimizehighmolecularweight discrimination, then it is easier tooverload theanalytical

column. Possibly thebiggest causeof overload is frompressure-pulsing the injectionport, as this

improves the transfer of all compounds to thecolumn.The requiredcapacity for your systemwill

bea functionof the specificcalibration standards and,more importantly, the injectionport.

From a capacity consideration, a 0.25mm ID columnwith0.25µm film thickness does not

have sufficient capacity for a 160ngper component standard. Figure4a shows the poor peak

shapeobservedwhen a column is overloaded. Increased capacity canbe achievedby

increasing columndiameter or film thickness.

When increasingcolumndiameter, the flow rateof thecolumncanbeaconcernwithbench-top

GC/MS systems.Manybench-topGC/MS systemsdonot have thepumpingcapacity for the

carrier gas flow that isneededwitha0.32mm IDcolumn.A0.28mm IDcolumncan increase

samplecapacitywithout exceeding thepumpingcapacityofmost bench-topGC/MS systems,

making it ideal for calibrating semivolatilecompounds from20 to160ngwithout overload.

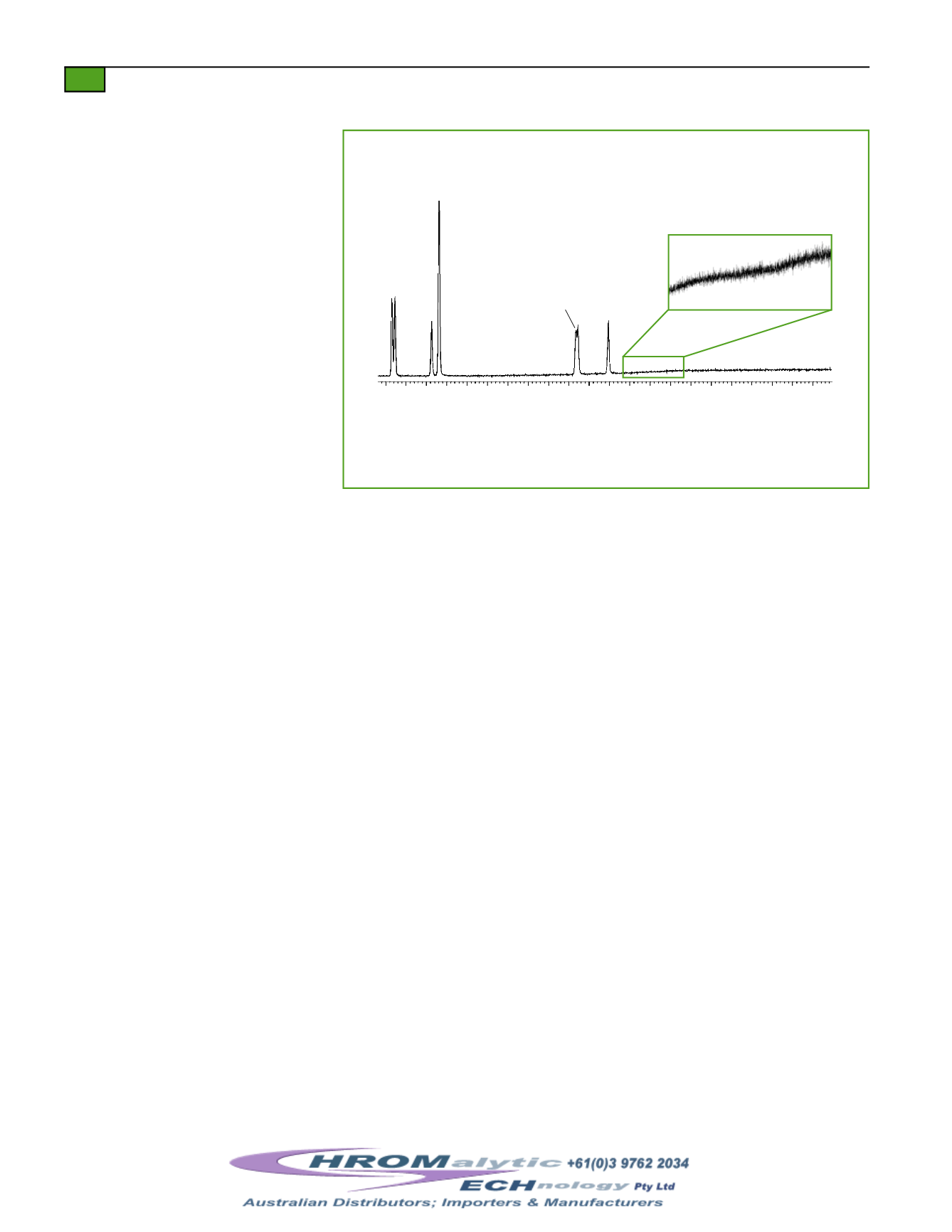

Alternatively, a0.25mm IDcolumnwitha0.5µm film thickness alsohas sufficient capacity to

handleacalibration from20 to160ngwithout exhibitingoverload. Figure4b shows excellent

peak shape for a160ng-per-component standardona30m, 0.25mm ID, 0.5µmRtx

®

-5SilMS

column.

The total

analysis time

shouldbe as short as possiblewithout sacrificing separationor

resolutionbetween compoundswith similarmass spectra. Payparticular attention to the

separationbetweenbenzo-b- andbenzo-k-fluoranthrene—they tend tobe themost difficult-

1 2

3

4

5

6 7

19

20

21

22

23

24

25

26

27

28

29 min.

1. benzo(b)fluoranthene

2. benzo(k)fluoranthene

3. benzo(a)pyrene

4. perylene-d12

5. indeno(1,2,3-cd)pyrene

6. dibenz(a,h)anthracene

7. benzo(g,h,i)perylene

30m, 0.25mm ID, 0.5µmRtx

®

-5SilMS (cat#12738)

20ng splitless injectionof CLP standard;

GC:

HP/Agilent 6890w/ 5973mass selective detector, scan range 35-550

AMU;

Ovenprogram:

40°C (hold2min.) to290°C@20°C/min. (hold0 min.) to303°C@2°C/min. (hold0min.) to

330°C@6°C/min. (hold1min.);

Carrier gas:

He@1.0mL/min. constant flow;

Inj. temp.:

300°C;

Det. temp.:

280°C

Website :

E-mail :

TelNo : 03 9762 2034 . . . inAUSTRALIA