ComparingFusedSilica toMetal

High temperature applications shorten the life-

time of fused silica columns due to deterioration

of the polyimide resinused tomake the columns.

When fused silica columns are exposed to oven

temperatures over 400°C the polyimide coating

becomes brittle and the deactivation of the col-

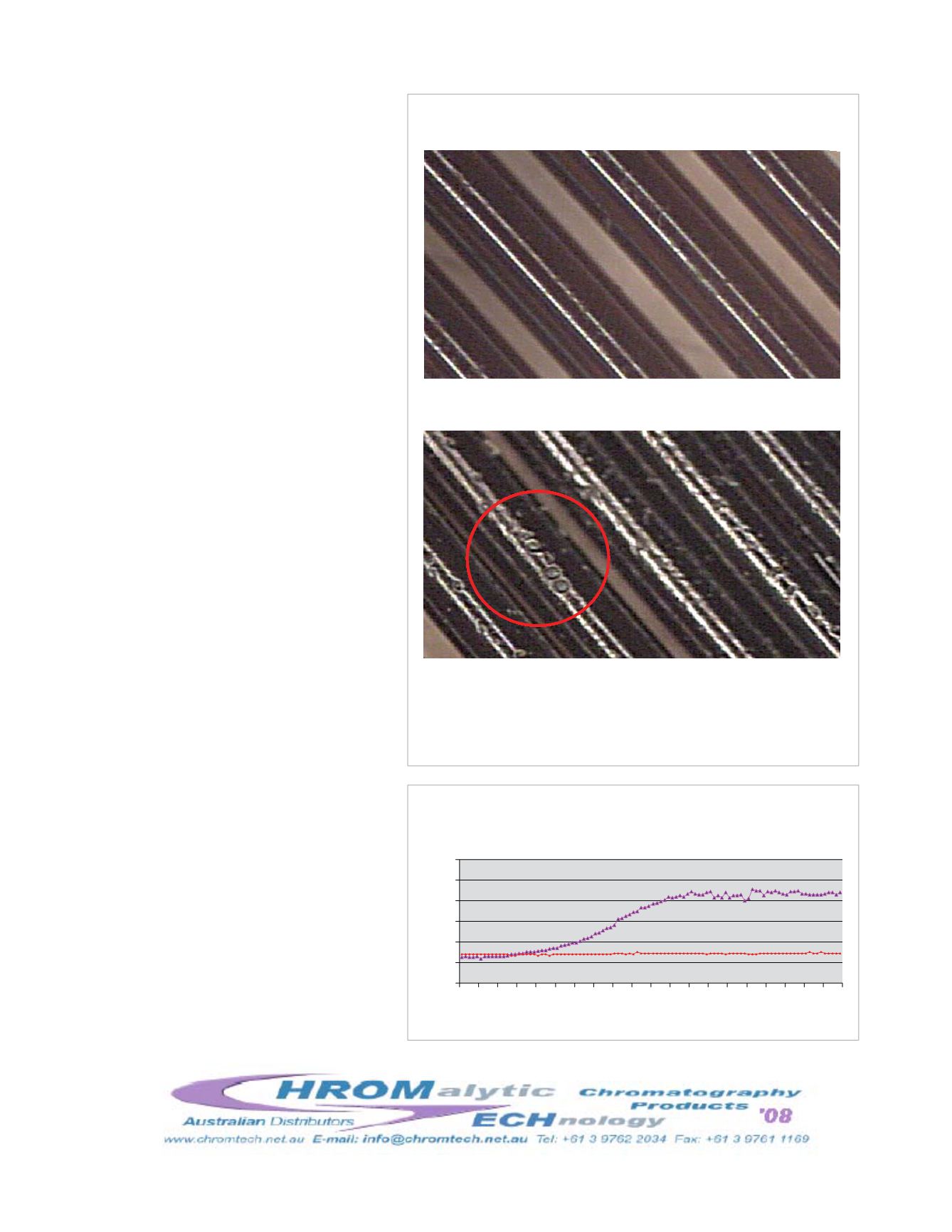

umn is compromised. Figure 3 shows the effect of

cycling a commercially available fused silica col-

umn to 430°C for 5minutes 100 times. Although

the columnwas labeled as stable up to 430°C, the

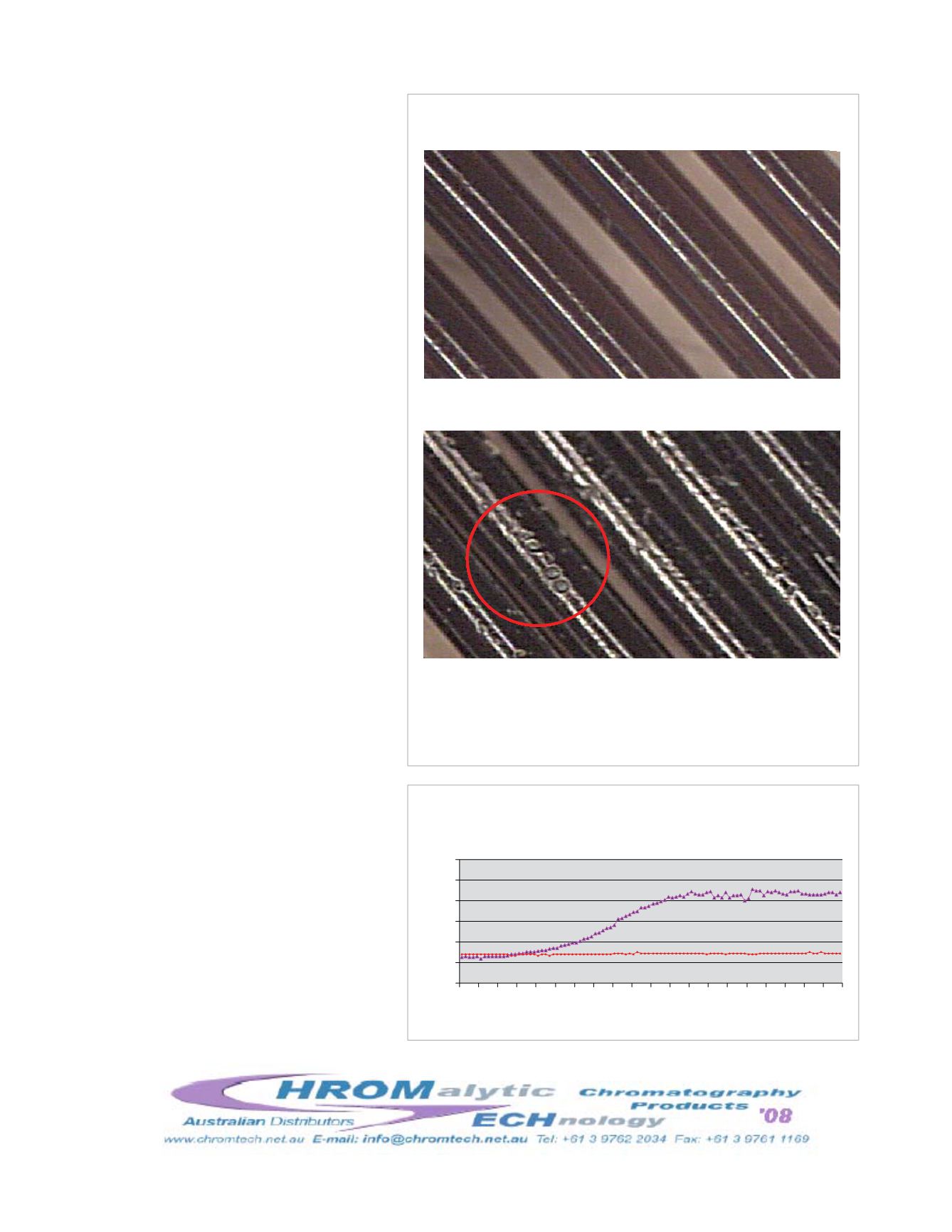

polyimide coating showsdamage.The inertnessof

the column also deteriorates as shown by the loss

of peak symmetry for the internal standard

butanetriol overmultiple injections (Figure 4).

Metal MXT®-Biodiesel TG columns are a better

alternative to fused silica columns. As shown in

Figure 4, they clearly outperform high tempera-

ture fused silica columns under the cycling condi-

tions required forbiodiesel analysis.MetalMXT®-

Biodiesel TG columns offer greater stability and

longer column lifetimes compared

to fused silica columns.

Figure3

Fused silicacolumns, labeledas stableup to430°C, show

significantpittingandbreakdown.

100 temperature cycles to430°C totaling500minutes at

maximum temperature.

Before

After

Figure4

Stablepeak shape for internal standardbutanetriol on

MXT®-Biodiesel TG columnsgivesmoreaccuratequantification.

0.8

1

1.2

1.4

1.6

1.8

2

1 8 15 22 29 36 43 50 57 64 71 78 85 92 99 100

Numberof Injections

Asymmetryvalue

HTFusedSilica

MXT-BiodieselTG

MXT® tubing is

more stable than

fused silica!

3

800-356-1688

•