8

Determining Trace Sulfur Compounds In Beer

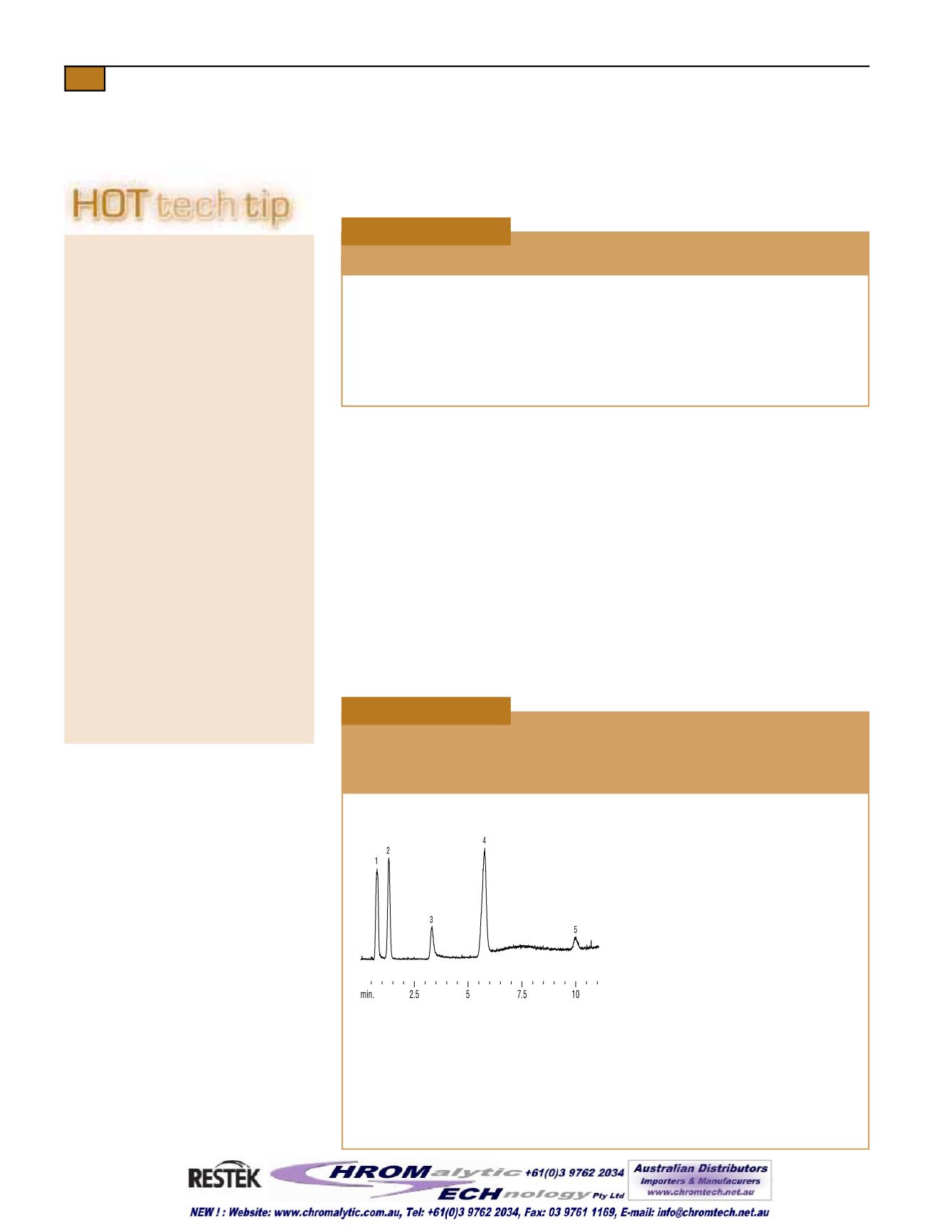

Trace sulfur compounds that are generated during the fermentation process can affect

the taste and aroma ofmalted products such as beers. Several common volatile sulfur

compoundsmight be present in beer at ppb or ppm levels (Table 1).

1m, 0.75mm ID Sulfinert

™

tubing

Rt-XLSulfur

™

100/120mesh (cat.# 19806)

Conc.:

sulfur standard@ 20ppb each inCO

2

Inj.:

1cc sample loop, 6-portValco

®

valve

Carrier gas:

helium

Flow rate:

10mL/ min.@ ambient temp.

Oven temp.:

60°C to 260°C@ 15°C/min. (hold 5min.)

Det. sensitivity: SCD, attn. x 1

Det. temp.:

800°C

GC_FF00491

1. hydrogen sulfide

2. carbonyl sulfide

3. methyl mercaptan

4. ethyl mercaptan and/or

dimethyl sulfide

5. dimethyl disulfide

Volatile sulfur-containing compounds found in beer at ppm to ppb levels.

Accuratemeasurement of reactive sulfur compounds at these levels requires ahighly inert

chromatographic system. Restek's Rt-XLSulfur

™

micropacked column contains a modi-

fied divinyl benzene polymer packed into Sulfinert

™

tubing, and is specifically designed

formonitoringppb levelsof active sulfur compounds.TheRt-XLSulfur

™

columnexhibits

low bleed and thermal stability to 300°C. This column provides excellent resolution of

hydrogen sulfide, carbonyl sulfide and sulfur dioxide.

Sample introduction into the column is a critical step in obtaining accurate analytical

results for sulfur compounds. In this application, abeer headspace samplewas introduced

onto thecolumnusingaValco six-port samplingvalve fittedwitha1mL sample loop.The

valve, sample loop, and all other surfaces in the sample pathwaywere deactivated using

our Sulfinert

™

deactivation process. The use of Sulfinert

™

-treated hardware is critical to

achieving a 20ppb detection level for sulfur dioxide and the other target sulfur com-

pounds (Figure 8).

hydrogen sulfide

isopropyl mercaptan

carbonyl sulfide

methyl ethyl sulfide

methyl mercaptan

n-propyl mercaptan

ethyl mercaptan

t-butyl mercaptan

sulfur dioxide

sec-butyl mercaptan

dimethyl sulfide

diethyl sulfide

dimethyl disulfide

isobutyl mercaptan

carbon disulfide

n-butyl mercaptan

t-amyl mercaptan

Low levels of reactive sulfur compounds in CO

2

(i.e., 20ppb) easily can

be detected using anRt-XLSulfur

™

micropacked column and a Sulfinert

™

treated sample pathway.

Sample, Transfer, and Analyze Sulfur

Compounds at Parts-per-Billion Levels

Our exclusive Sulfinert

™

process is the

next generation of metals passivation

treatments, developed specifically for

deactivating metal surfaces that contact

organo-sulfur compounds. Untreated

stainless steel adsorbs or reacts with

hydrogen sulfide, mercaptans, and other

active sulfur-containing compounds.

Applied to a stainless steel surface, a

Sulfinert

™

layer prevents these com-

pounds, and other active compounds

(e.g., amines), from contacting the reac-

tive metal surface. Combine custom-

deactivated sample storage and transfer

components with stock Sulfinert

™

-treated

parts topassivate your entire system, and

obtain highly accurate information about

sulfur compounds in your samples.

Additional Important Features

Durable and flexible - will not crack

or flake.

Stable to 400°C.

Nomemory effects, as seenwith

polymeric surfaces.

Table 1

Figure 8