Basic HTML Version

Trademarks:

Kel-F

®

is a registered trademark of the 3M Company

Omni-Lok

TM

is a trademark of Omnifit Ltd.

Rev. 0205

Large Electric Rotary Valves with Smart Actuator (contd.)

Ordering Information

P/N

Description

Voltage

Ports

Pack

Size

11101A/11106

Smart Actuator with 6 port loop injection valve USA power lead

100 to 240 VAC 6

1

11101A/11107

Smart Actuator with 7 port distribution valve USA power lead

100 to 240 VAC 7

1

11101A/11110

Smart Actuator with 10 port loop injection valve USA power lead

100 to 240 VAC 10

1

11101A/11111

Smart Actuator with 11 port distribution valve USA power lead

100 to 240 VAC 11

1

11101E/11106

Smart Actuator with 6 port loop injection valve European power lead 100 to 240 VAC 6

1

11101E/11107

Smart Actuator with 7 port distribution valve European power lead

100 to 240 VAC 7

1

11101E/111010

Smart Actuator with 10 port loop injection valve European power lead 100 to 240 VAC 10

1

11101E/11111

Smart Actuator with 11 port distribution valve European power lead

100 to 240 VAC 11

1

11101U/11106

Smart Actuator with 6 port loop injection valve UK power lead

100 to 240 VAC 6

1

11101U/11107

Smart Actuator with 7 port distribution valve UK power lead

100 to 240 VAC 7

1

11101U/11110

Smart Actuator with 10 port loop injection valve UK power lead

100 to 240 VAC 10

1

11101U/11111

Smart Actuator with 11 port distribution valve UK power lead

100 to 240 VAC 11

1

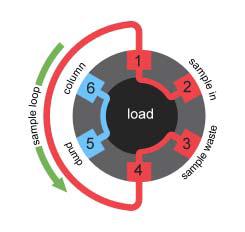

The images below show Omnifit loop inject valves in use as sample injection devices in a chromatography system. These are

the most common applications but the use of the valves is not limited to these.

Application and set up notes.

6 port loop inject valve used as a sample injector

With the valve in the load position the sample can be injected into the

sample loop while the mobile phase is pumped directly through to the

column.

When the valve is switched to the inject position, the pump is then

connected to the sample loop and the sample is carried onto and

through the column. The ‘sample in’ and ‘waste’ ports are joined but

isolated from the loop.

It is suggested that ports are connected to the corresponding lines as

shown. This ensures that the flow of the mobile phase is in opposite

directions during the load and inject operations.

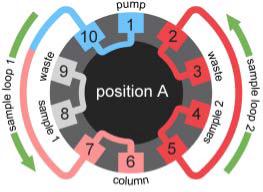

10 port loop inject valve used as a sample injector

This valve allows alternate injection from two different sample loops,

either identical or of different sizes. This application can alternatively be

satisfied with a 4 port switching valve and a 6 port loop inject valve.

With the valve in position A, sample 2 can be loaded into sample loop 2

while the mobile phase is pumped through sample loop 1 and carries

sample 1 onto the column. The ‘sample 1 in’ and ‘waste’ ports are

connected but isolated from the loop.

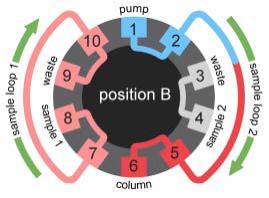

When the valve is switched to position B, the pump is connected to

sample loop 2 and sample 2 is carried onto and through the column.

The ‘sample 2 in’ and ‘waste’ ports are connected but isolated from the

loop. Whilst sample 2 is pumped onto the column, sample loop 1 can

be re-loaded.