Glovebox Systems

GLOVE-BOX

The MRC high efficiency line of Inert Gloveboxes and Gas Purification Systems are designed specifically for production

and large scale research applications where time management and maximum efficiency is crucial. All MRC brand

Glovebox Systems are manufactured using the strictest of Quality Assurance measures and with only highest quality

components including Swagelok compression fittings and valves, Edwards Vacuum Components and Allen Bradley

PLC Controls.

The Glovebox design is based on a modular platform allowing customers to expand existing Gloveboxes to meet

increasing working space requirements. Expansion features include additional antechambers for thru flow work

processes, cold storage freezers, process vacuum ovens and furnaces and full line of accessories. The Gas Purifiers

provide a < 1 ppm O

2

and H

2

O Inert Atmosphere required for a multitude of air sensitive applications.

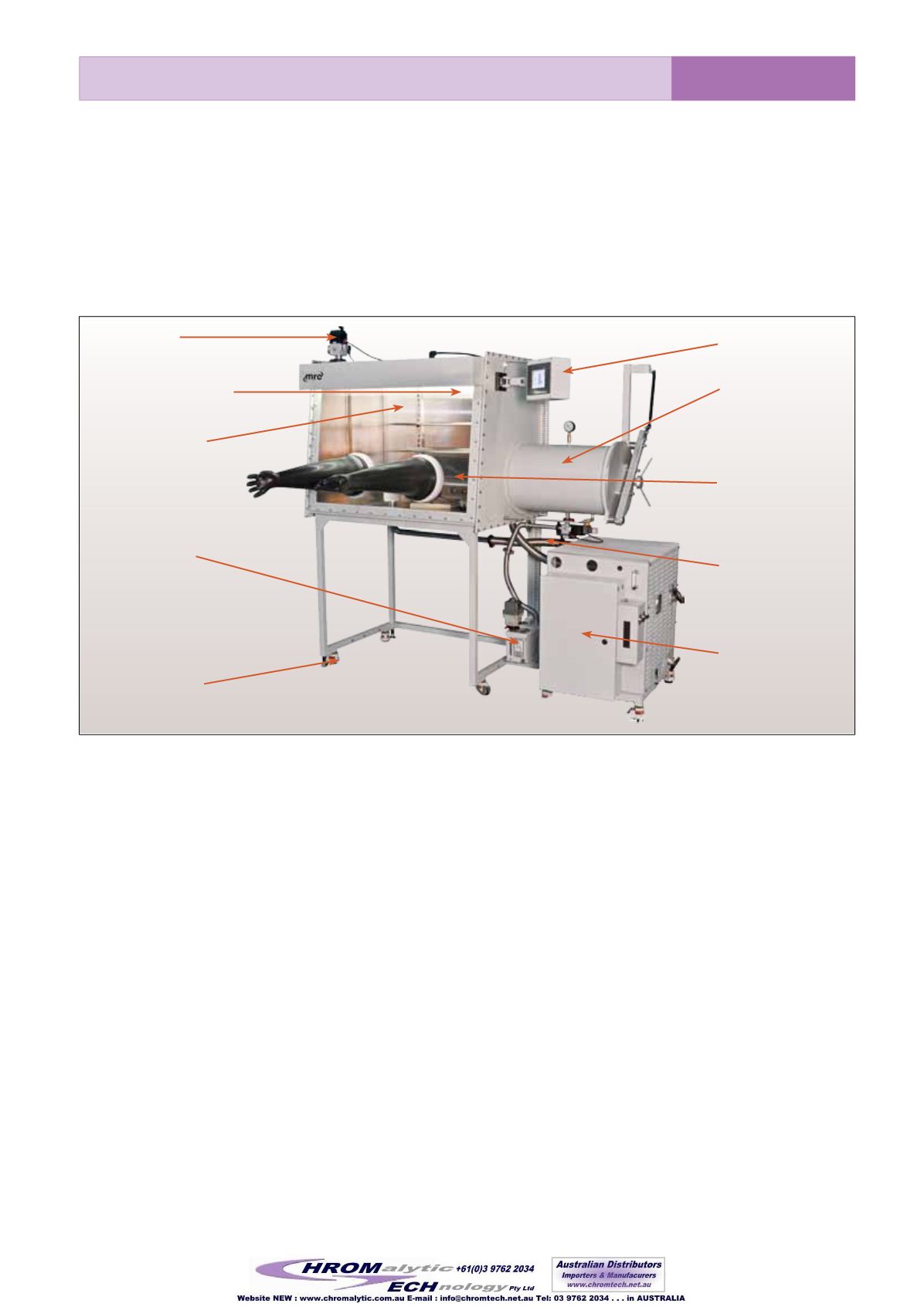

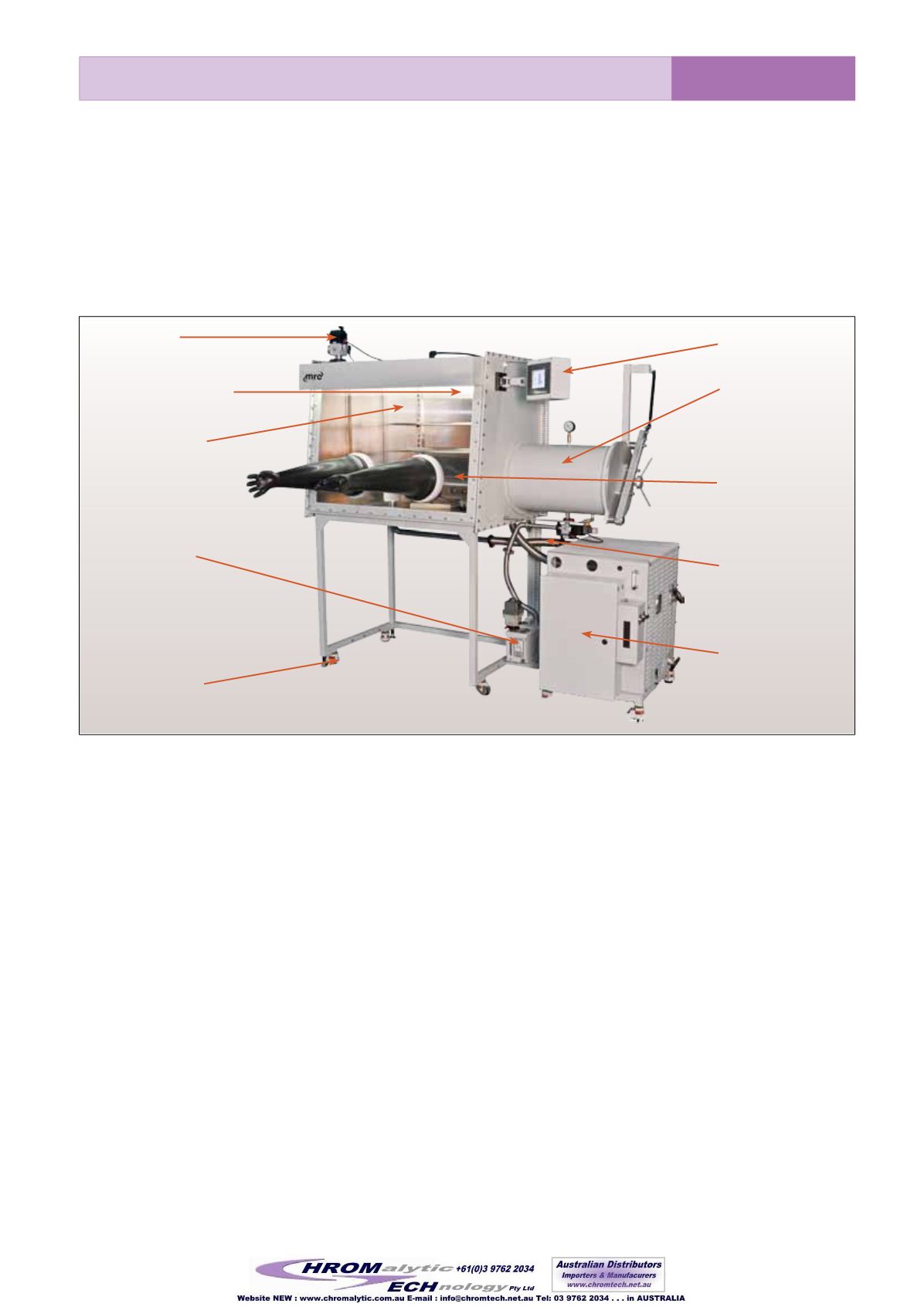

Inert Glovebox & Gas Purification Systems

Purge Valve

Front-Mounted Light

Adjustable Internal

Shelving

Vacuum Pump

Leveling Casters

Color Touch HMI

Large

Antechamber

Delrin Glove Ports

All Stainless Steel

Gas Flow Piping

and Fittings

Gas Purification

System

-Single column

standard.

-Dual column

available.

Features:

●

304 Type SS Construction

●

Modular Design

●

All Stainless Steel Gas Flow Piping & Fittings

●

Electrical Feed-Through with Power Strip

●

Gas and Vacuum Feed Through

●

Foot Pedal for Manual Pressure Control

●

Front Mounted Light

●

MR-10 LEXAN Chemical Resistant Window

●

Delrin Glove Ports

●

Powder Coated Finish

●

Color Touch Screen HMI

●

Gas Purifier < 1 ppm 0

2

and H

2

0

●

Large Vacuum Chamber

●

Rotary Vane Vacuum Pump

●

Variable Speed 0-60 CFM Circulation System

●

Automatic Regeneration

●

Automatic Pressure Control

●

Automatic Column Valves

●

Adjustable Storage Shelves

●

Locking Leveling Casters

●

Power Strip.

Specifications:

●

Modular Design

●

Inside Dimensions - W1250mm x H900mm x D780mm

●

Material of Construction - US type 304 Stainless Steel

●

Interior Finish - Brushed

●

Exterior Surface - Powder Coated Gray

●

Stand - Powder Coated Gray, Leveling Feet & (asters

●

Electrical Feed Through - NW-40 Blanked

●

Gas & Vacuum Feed Through - Bulkhead Fitting

●

Dust Filters - .3 Micron HEPA Gas Inlet / Outlet

●

Electrical Outlet - Six Position Power Strip

●

Shelves - Three (3) Shelves, Height Adjustable, US type 304

Stainless Steel

●

Glove Ports - Delrin- Chemical Resistant

●

Gloves - Butyl - Different Sizes and Materials Available

●

Window - MR-10 LEXAN 3/8” Thickness, Chemical

Resistant and Inclined to Reduce Glare. Safety Glass

Available

●

Lighting - Front Mounted Fluorescent Lamp

●

Leak Rate - < 0.05 vol%/hour (ISO 10648-2) Factory Tested

●

Leak Rate - < 0.05 vol%/hour (ISO 25412) Factory Tested.

Control System & Operator Interface:

●

Allen Bradley MicroLogix 1200 Programmable Logic Controller (PLC)

●

Color Touch HMI - 6 inch Screen

●

HMI - Mounted on Articulating Arm

●

Data Logging - Available Per Request

●

O

2

& H

2

O Display - Available Per Request

●

Foot pedal for box pressure adjustment

●

Electrical requirement: 230V, 50-60Hz, lOA or 115V, 50-60Hz, 20A.

●

Power Consumption May Vary Depending on Accessories.

82