Advanced Features

• Metal-to-metal diaphragm seal

No possibility of gas contamination

• Capsule

®

seat

Increased serviceability and life

• 316L stainless steel diaphragm

No inboarddiffusion

• Orientable captured vent capable

Safety in any installation

• Lowwetted surface area

Minimal purge requirements

• Field-adjustable pressure limit

Safeguarddownstream equipment

• Pipe away relief valve

Safely vent exhaust gases

• Delivery pressure range easily changed

Maximumflexibility

Materials

Specifications

400Advantage

Typical Applications

CRNOH5216.5C

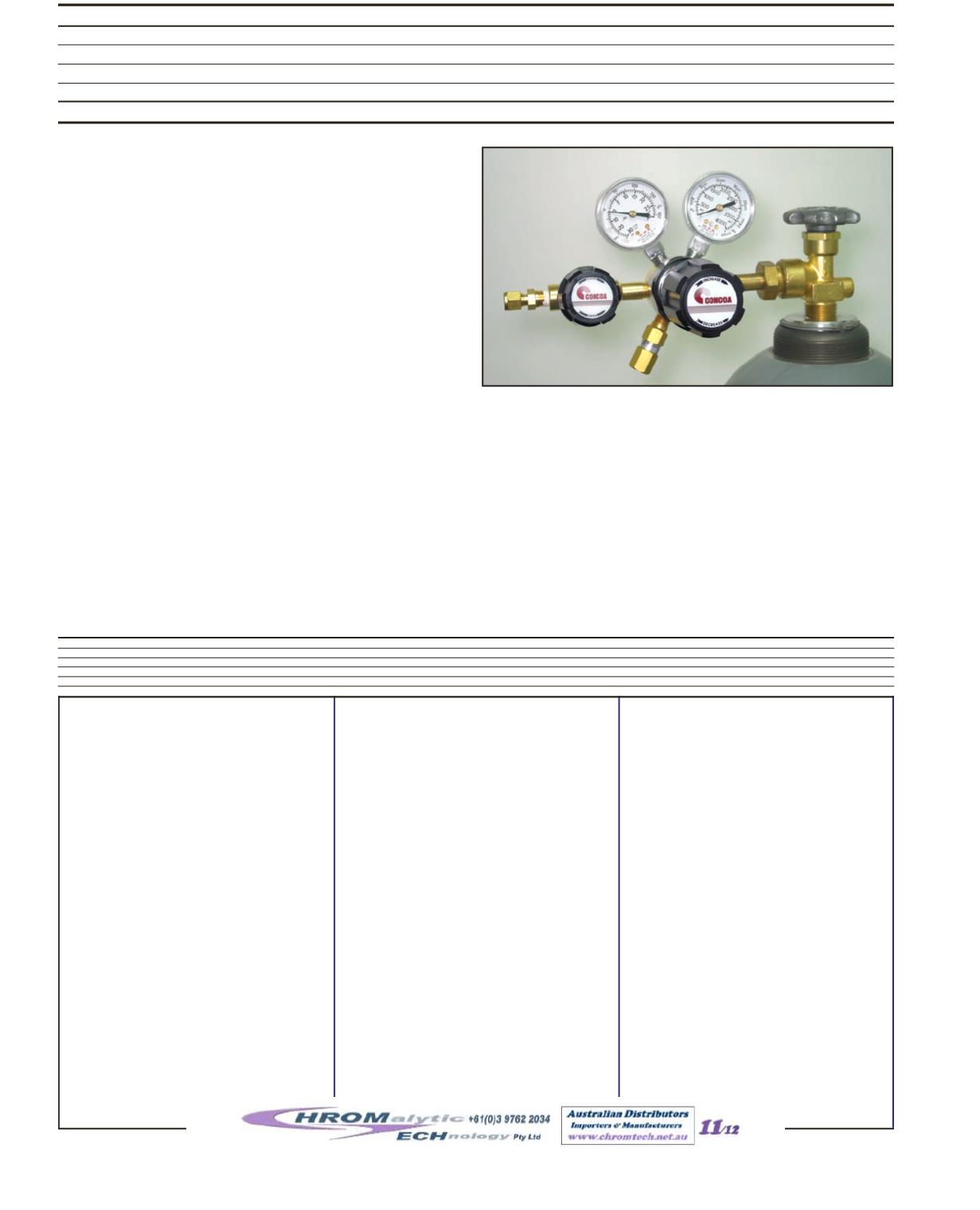

401 Series Regulator

Single Stage

Brass BarstockBody

Six-Port

Configuration

316L Stainless Steel

Diaphragm

Body

Brass barstock

Bonnet

Chrome Plated barstock

Seat

PTFE

PCTFEwith4500PSIG inlet option

Filter

10micron sintered bronze

Diaphragm

316L stainless steel

Internal Seals

PTFE

Maximum Inlet Pressure

3000PSIG (210BAR)

4500PSIG (310BAR) optional

Temperature Range

-40°F to 140°F (-40°C to 60°C)

Gauges

2” diameter chrome plated

Ports

¼” FPT

HeliumLeak Integrity

1 x 10

-9

scc/sec

Cv

0.1

Weight (401-1331-580)

3.99 lbs. (1.81 kg)

• Gas and liquid chromatography

• High purity carrier gases

• Zero, span and calibration gases

• High purity chamber pressurization

• Liquefied hydrocarbon gas control

• Control of cryogenic gases

• Brass barstock body

Smooth surface finish

• Front and rear panel mountable

Versatile system configuration

• Pressure ranges 0-15 to 0-500PSIG

Broad range of applications

The401Seriesregulatorsare intended for

primarypressurecontrolofnoncorrosive,

high purity or liquefied gases, or for

applicationswhereminorfluctuations in

outlet pressure due todiminishing inlet

supply can be tolerated.

401-1331 shown

NEWwebsite 2011 :

E-mail:

TelNo : 03 9762 2034 . . . inAUSTRALIA