Phone: 800-356-1688 or 814-353-1300

13

Oven

Some canister cleaning systems are incorporatedwithin an oven. The supply

line for the humidified air stream and the line to the vacuum system are

plumbed directly into the oven. In this arrangement the entire canister,

including the valve,will be heated, and thiswill help remove contaminants if

both the valve and the canister aredirty.Typically,whenusingheat, it is help-

ful to create steam from thehumidified air stream.Anoven temperatureof at

least 120°C is required, but higher temperatures often are used. Remember

that heat can shorten the lifetime of theNupro valve on a SUMMA® canister

(see step3 inCleaningMethod, below).

Space is a concern with oven systems. Most commercial ovens are not very

largeand this restricts thenumberof canisters that canbecleanedatone time.

However, clean-up times are shorter with heat than without heat, so more

cleaning cycles canbe completed in aweek.

Heat Bands

Abandheaterplacedaround theequatorof thecanister typicallywill becapa-

ble of heating the canister to approximately 130°C. There is a heat gradient,

and the valve might only receive radiant heat (approximately 70-100°C). In

most sampling situations, however, this lower temperature should be suffi-

cient for effectively removing contaminants from the valve.

InsulatedHeat Jackets

Insulated heat jackets can be obtained to surround and heat each canister.

These jackets typicallyhave a siliconeorTeflon®-coated fiberglass fabric exte-

rior and a fiberglass insulation interior. Some operate at a fixed temperature;

others can provide variable temperature, up to 400-500ºF. Restek’s heating

jacket, described at right on this page, offers significant advantages overmost

other commercial designs,whichdonot encompass the valve area.

InfraredHeat

An infrared heating system includes an infrared heat source and a reflective

panel similar to thecylinderdrying rackonagascylinder system.The infrared

source and the reflective panel are placed on opposing sides of the canisters.

Infrared rays from the source heat the canisters; rays that pass the canisters

strike the reflective panel andheat the canisters from the opposing side.

TheCleaningSystem

Thecleaning systemmustprovideahumidifiedair streamand includeagood

vacuum source, acold trap tocollect impuritiesduringcleaning, andaccurate

gauges to read vacuum and pressure. A heat source is optional, but is highly

recommended in some circumstances, as discussed above. The system canbe

designed toclean4 to24 six-liter canisters.Figure8 (page14) shows anexam-

ple of a “homemade” system designed to clean 24 six-liter canisters. This

designdoesnot employheat,but aheater easily canbe added (seeHeat orNo

Heat, page 12). It provides a humidified air stream to all canisters and the

roughing pump on the bottom shelf is the vacuum source. This system is

computer operated tominimize labor, but this is not necessary.

CleaningMethod

1. Connect all canisters to the cleaning system, then release anypressure

within anyof the canisters. Put the systemunder vacuum, to evacuate the

canisters.USEPAMethodTO-14A/15 recommends evacuating the sys-

tem to50mTorr for 1hour, but a reducedpressure of 23-25"Hg is suffi-

cient for general cleaning.

2. After the canisters have beenunder vacuum for approximately 1hour,

pressurize the canisterswithhumidified air or nitrogen*. Pressurization

will dilute the impurities and themoist airwill hydrolyze them.

Pressurize canisters to5psig if theywill beheatedor to30psig if they

will not beheated. Proceed to step3when the systemhas equilibrated at

the designatedpressure.

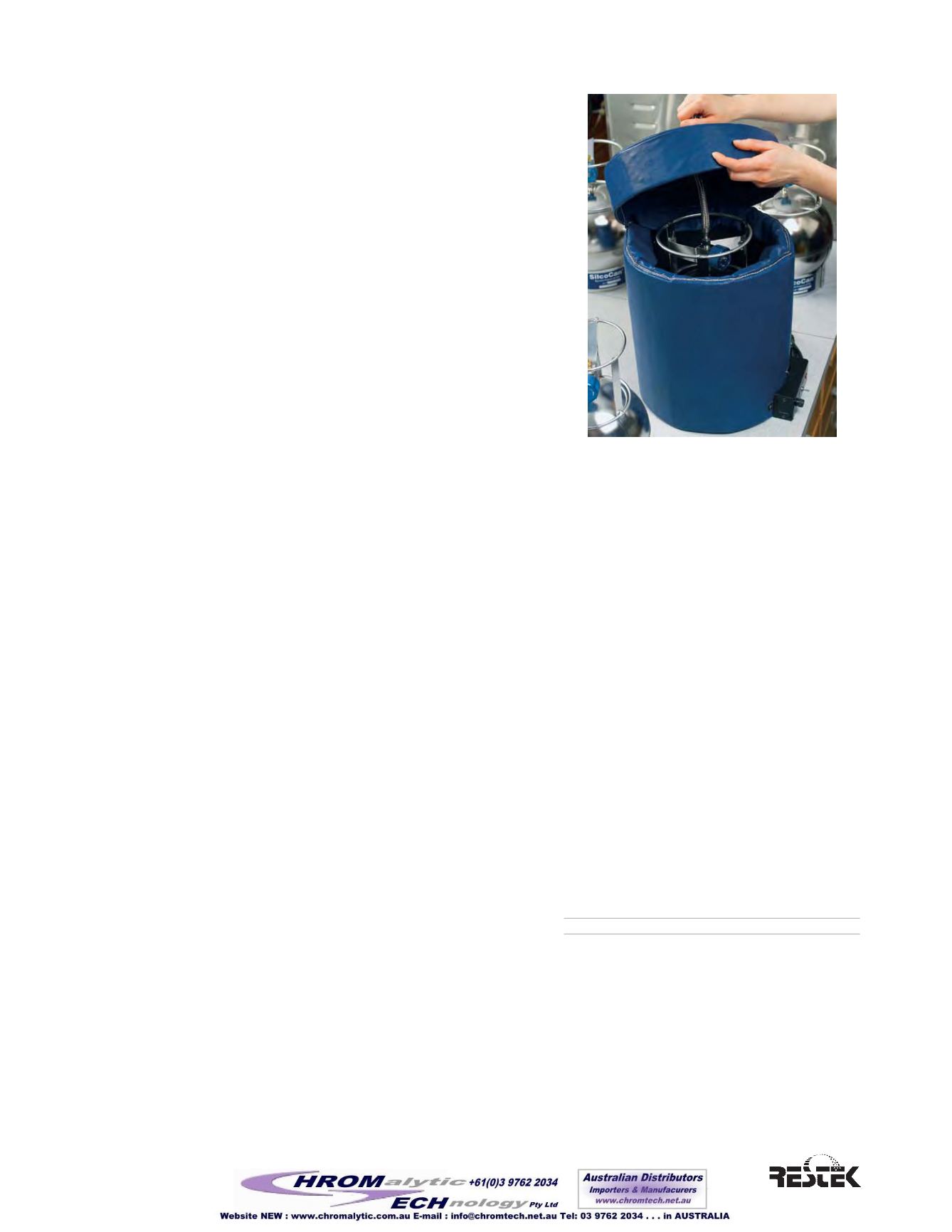

Theultimate in controlledheating,

for reliably cleaningyour air canisters!

Description

qty.

cat.#

Air Canister Heating Jacket (110 volt)

ea.

24123

AirCanisterHeatingJacket

• Closely simulates oven environment—heats

entire canister.

• Two temperature settings, 75°C and150°C.

• Prevents sample condensation, for accurate sub-

sampling.

• Easily fits canister up to6 liters.

• Lightweight; comfortable to the touchwhen

heated.

• Connect up to fiveCanisterHeating Jackets to

one 15 amp circuit.

The Restek Canister Heating Jacket will help you

cleanyour canisters faster andmoreefficiently.The

novel design ensures the entire canister, including

the valve, is heated during the cleaning cycle, to

remove contaminants most effectively. It also can

be used to keep the sample heated during aliquot

removal, which helps prevent condensation and

assure accurate data for largermolecules. The two

heat settings let youmatch the temperature to the

volatility of your sample components. If you try

one in your system,we think you’ll wantmore.

*

please

note

If you are cleaning SilcoCan

TM

canisters, andwill be using heat,

use humidified nitrogen, not air.