4

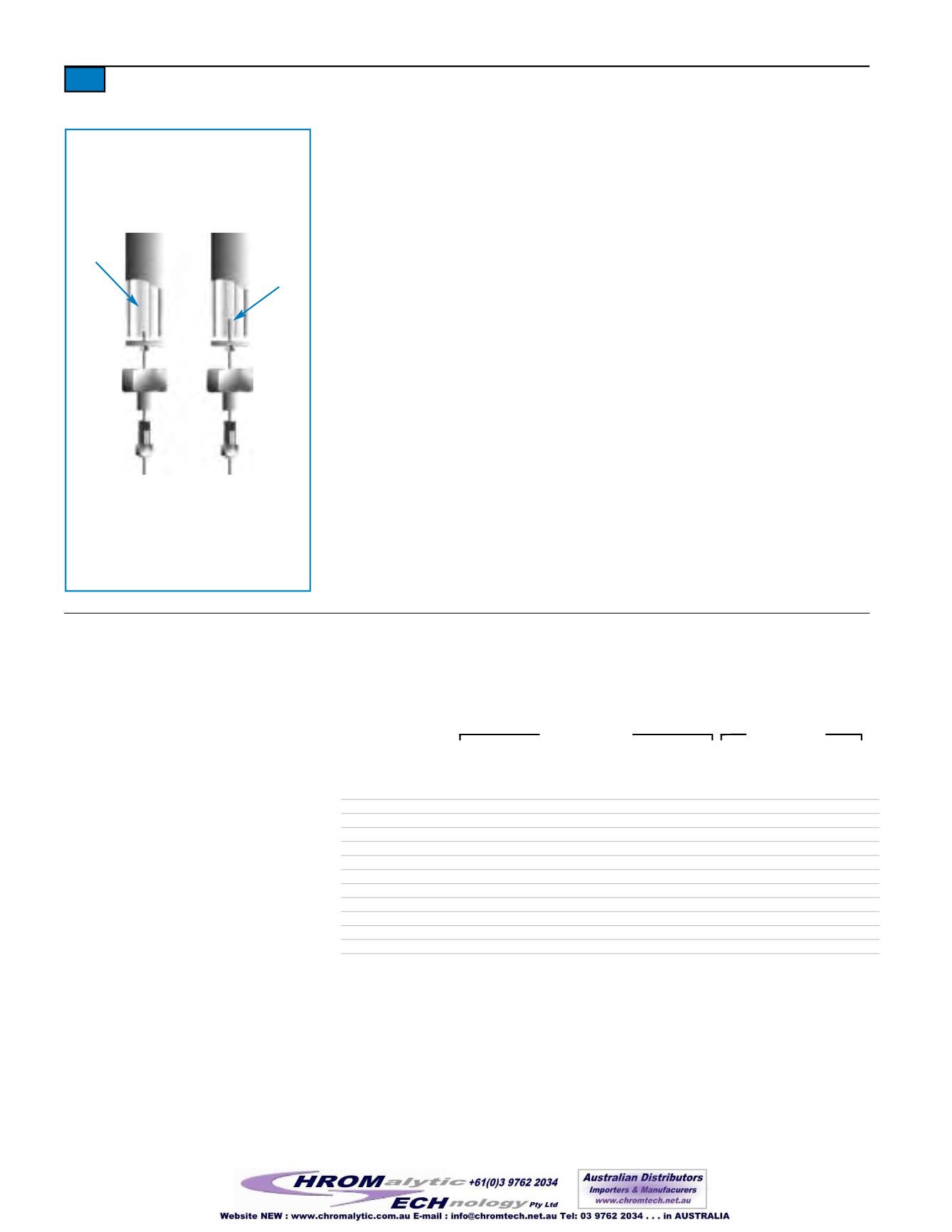

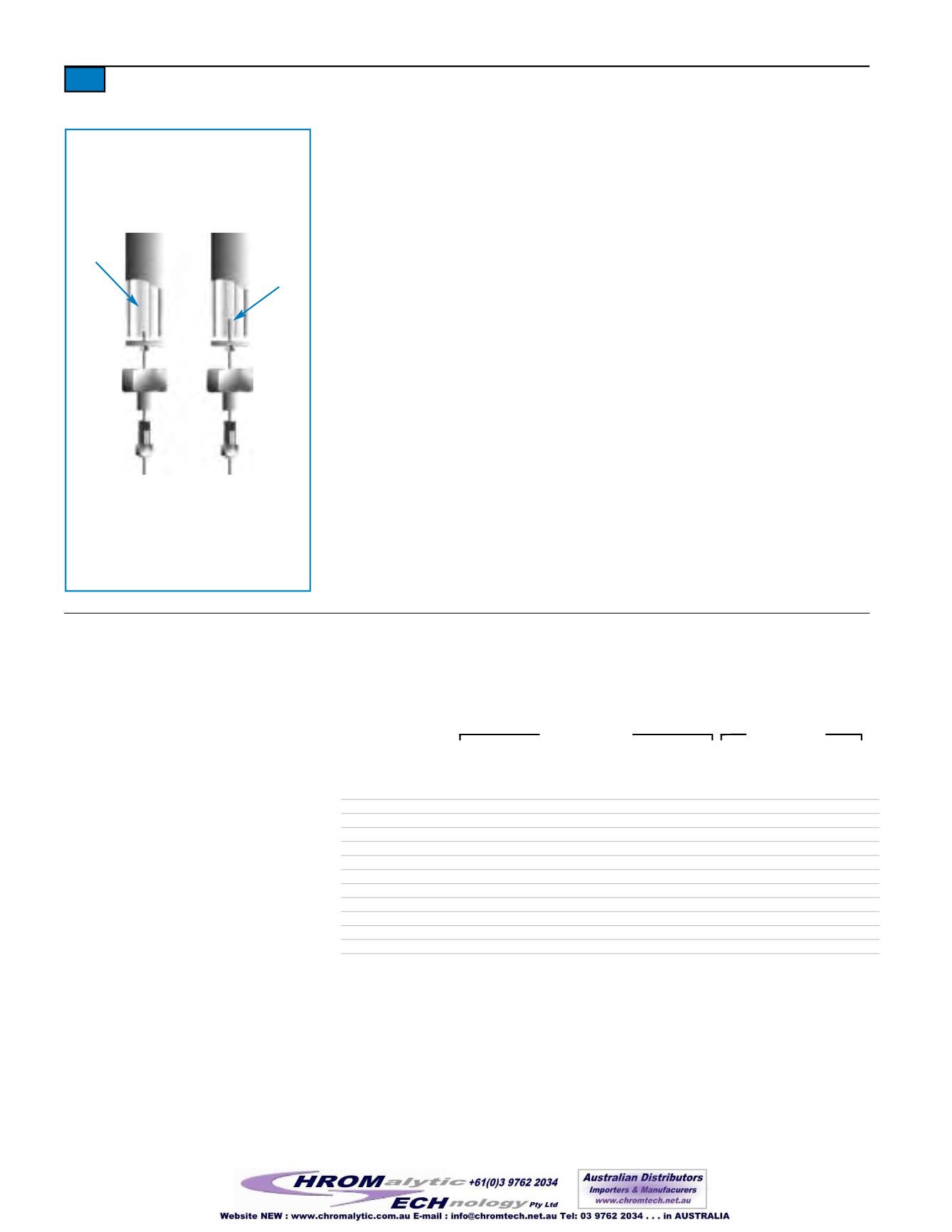

We compared a splitless injection liner and a direct injection liner installed in a capillaryGC

injector (Figure 2). Notice that the splitless injection liner allows the sample vapor to contact

themetal inlet seal at the base of the injection port. Sample vapor potentially can adsorb

onto thismetal surface, or can condense in the area below the column inlet. Either occur-

rence can cause low response for active or highmolecular weight compounds. In contrast,

because the direct injection linermakes a positive seal with the column inlet, all sample

vapor is directed onto the column and cannot interact withmetal injection port surfaces.

Therefore, sensitivity for active and highmolecular weight compounds is significantly

improved.

Table I summarizes the chromatographic results obtainedwhen amixture containing active

and highmolecular weight compoundswas injected into three different splitless injection

liners and two different direct injection liners. Themost typical injection port liner used for

splitless injections is a straight liner with a 4mm internal diameter, packedwith deactivated

fused silica or glasswool (A). The benefit in using a straight liner packedwithwool is that

thewool enhances sample vaporization and thereby improves the responses for highmolecu-

lar weight compounds (represented in this analysis by benzo(b)- and benzo(k)fluoranthene).

However, when the relative responses obtained by using a straight liner packedwithwool

(A) are compared to responses from two splitless injection linerswith a gooseneck restric-

tion of the internal diameter at each end (B andC), it is apparent that the active probes (2, 4-

dinitrophenol, nitrophenol, and pentachlorophenol) were completely adsorbed in the injec-

tion port when the straight liner packedwithwool was used.A double gooseneck liner (B)

improves the response for active compounds by confining the sample cloudwithin the buffer

volume of the liner. This reduces sample contact with themetal support disk in the injector

and, thus, reduces adsorption.A double gooseneck liner with an internal glass spiral (C) not

only provides good response for active compounds, but also provides better vaporization of

high boiling analytes compared to a double gooseneck liner without a glass spiral. Because a

inlet seal

splitless

liner

press-tight

seal

Figure 2.

Splitless and direct injection liners

installed in a splitless capillary injector.

The data illustrate that direct injections improve

responses in general, but especially improve re-

sponses for active high molecular weight com-

pounds compared to splitless injections. A double

gooseneck splitless injection liner provides better

responses than an open, wool-packed splitless in-

jection liner, but it is not until a positive seal is

made between the liner and the capillary column

(D and E) that significant improvements are

observed.

Analystswhousedirect injections insteadof split-

less injections can expect better overall sensitivi-

ty and greater response factors for both active

and highmolecular weight compounds.

30m, 0.32mm ID, 0.25µmXTI-5 column (cat.# 12224),

splitless or direct injection of 1µLXTIMix,

concentration = 29ng/µL.

Oven temp.:

100°C to 285°C@ 6°C/min.,

then to 360°C@ 30°C/min.

(hold 5min.)

Inj./Det. temp.:

250°C/360°C

Carrier gas:

hydrogen

Linear velocity:

40cm/sec. set@ 100°C

FID sensitivity:

8 x 10

-11

AFS

Splitless hold time: 0.75min.

A: splitless injection, 4mm ID injector liner packedwith glasswool (cat.# 20781)

B: splitless injection, double gooseneck injector liner (cat.# 20784)

C: splitless injection, cyclo double gooseneck injector liner (cat.# 20895)

D: direct injection, Uniliner

®

injector liner (cat.# 20335)

E: direct injection, Cyclo-Uniliner

®

injector liner (cat.# 20337)

All analyses conductedwith anAgilent 5890 II GC equippedwith an autosampler

and a dirty inlet seal.

Response Relative to C14

Splitless Injection

Direct Injection

A

B

C

D

E

4mm ID

Double

Cyclo

Analyte

wool-packed Gooseneck Double Gooseneck Uniliner

®

Cyclo-Uniliner

®

benzoic acid

NA

0.90

1.23

1.06

1.21

C14

1.00

1.00

1.00

1.00

1.00

2,4-dinitrophenol

NA

0.33

0.46

0.68

0.58

nitrophenol

NA

0.73

0.93

1.24

1.17

nitroaniline

1.03

0.78

0.93

1.20

1.20

pentachlorophenol

NA

0.45

0.55

0.70

0.66

carbazole

2.01

1.43

1.69

2.17

2.06

C20

1.13

0.89

0.98

1.16

1.09

C21

1.08

0.81

0.92

1.10

1.04

C22

1.13

0.81

0.94

1.15

1.09

benzo(b)fluoranthene

2.18

1.18

1.90

2.22

2.47

benzo(k)fluoranthene

2.09

1.15

1.84

2.27

2.36

Table I.

Responses for active and highmolecular weight compounds are greater with direct

injection, compared to the same injector configured for splitless injection.

splitless injection

liner

Uniliner

®

direct

injection liner

AUniliner

®

direct injection liner prevents

the sample from contactingmetal surfaces

in an injection port, so sample adsorption

and catalytic decomposition are reduced

and responses for highmolecular weight

compounds are greater.

NA –Peak not quantifiable; data not available.