026

7

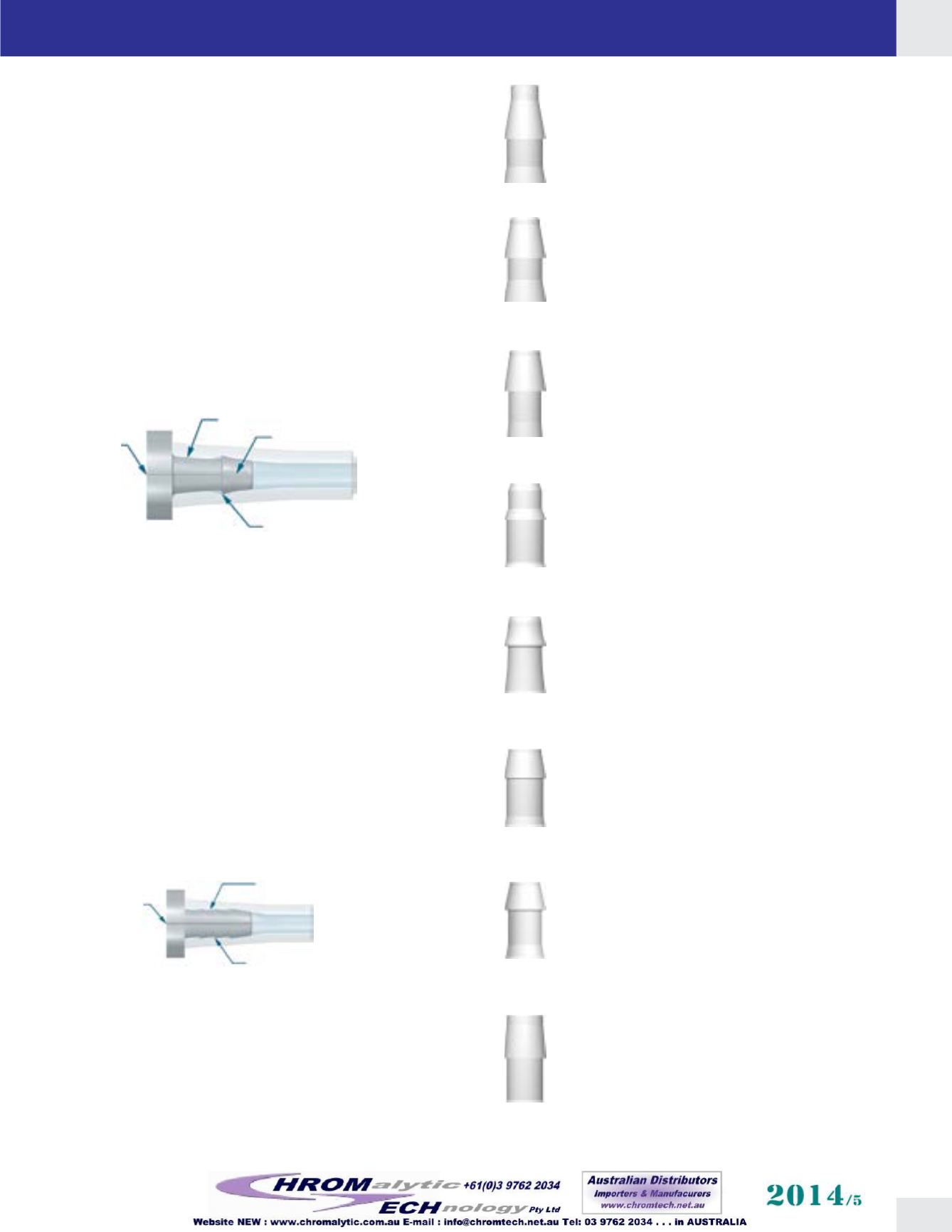

Our Single Barb Concept

Many designers are not aware of the benefits of using a single

barb versus a multi-barb fitting, but the barb design greatly

affects the security of your tube connection.

Because of the shape of a barb, it is impossible to injection mold

any but the first barb without a parting line. The parting line

creates a potential leak path that becomes more pronounced as

the tooling wears, increasing the likelihood of failure.

Two other problems exist with multiple barb fittings. First,

it is impossible to fabricate tooling that creates a perfectly

sharp edge on each barb of a molded multi-barb fitting – a

feature critical to the performance of the connection. Second,

multiple barb fittings do not allow the tubing to relax behind

the first barb. Because the tubing “bridges” from barb to barb

it is not allowed an uninterrupted interface with the fitting.

This results in compromised pressure and tensile capacities.

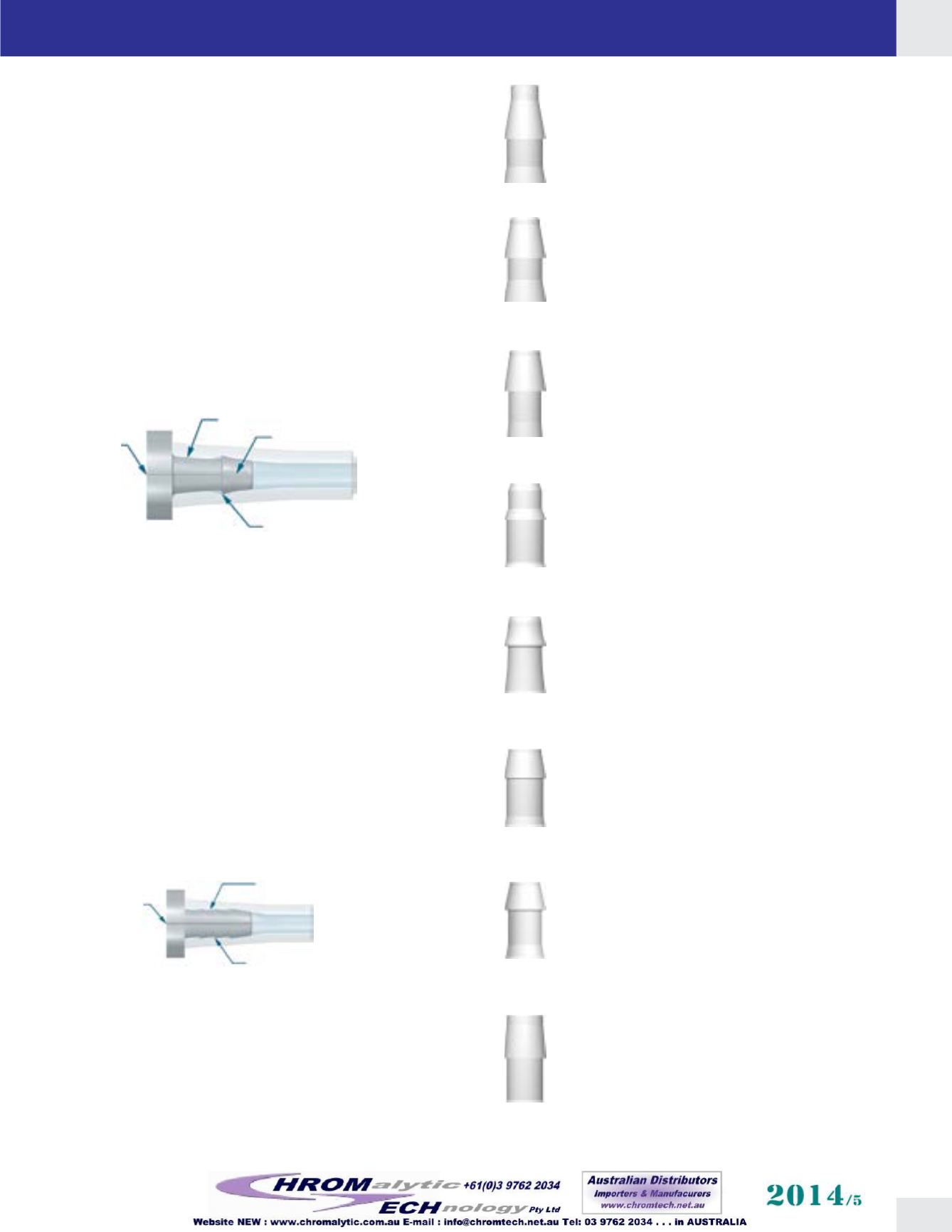

Value Plastics

®

single barb design avoids these shortcomings.

Our expert tooling design assures the sharpest edge

possible allowing the barb to “bite” into the tubing. Then, the

cylindrical surface behind the barb allows the tubing to relax

against the fitting. The result is a connection with excellent

tensile and pressure performance.

MULTI BARB

MOLD PART LINE:

Potential leak path on

critical sealing surfaces.

Bridging effect of multiple

barbs prevents tubing

from relaxing behind barb.

Tool design results in radius

on corner of barb. Worn

or poorly fit tool also prevents

“bite”, allowing for potential

part failure.

The data presented here is for reference only. It was compiled to provide our customers with a means of comparing the characteristics of components at the time of publication. The particular conditions of your

use and application of our products are beyond our control. Thus, it is imperative that you test our products in your specific application to determine their suitability. All information is provided without implied or

expressed warranty or guarantee by Value Plastics

®

or other manufacturers. None of the information provided constitutes a recommendation or endorsement of any kind by Value Plastics

®

.

VALUE PLASTICS’ BARB:

The Most Secure Connection

The

CLASSIC SERIES

is characterized by a longer barb that

extends the sealing surface of the fitting. Tubing is expanded

from 42% to 69% above its nominal ID.

The

200 SERIES

offers outstanding performance characteristics

when used with flexible tubing. Tubing is expanded by 50%

above its nominal ID, permitting high-pressure capabilities.

The

300 SERIES

offers outstanding performance characteristics

when used with flexible tubing. Tubing is expanded by 35%

above its nominal ID, permitting high-pressure capabilities in

the larger tube sizes.

The

400 Series

provides easy assembly while maintaining

excellent pressure and tensile capabilities. Originally created for

semi-rigid tubing, this series is preferred for applications where

tensile/pressure properties are not highly critical, or when ease

of assembly is desired. The 400 Series expands the tubing 25%

above its nominal ID.

The

500 SERIES

profile is composed of blended radii, giving it

the distinct look. Each barb is designed to accommodate a range

of tube sizes and tube types. Consideration should be given to

flow restriction, pressure capability, and the force required for

assembly of the tube.

The

600 SERIES

barbs are designed for use with silicone, C-Flex

®

and PVC tubing sizes commonly used in biopharm and other

applications. Tubing is expanded from 18% to 34% above its

nominal ID to maintain a low profile and ease of assembly, and

the straight barb stem facilitates use of recommended cable tie

retainers or hose clamps.

The

700 SERIES

barb is designed for use with Value Plastics’ XQ

Series quick connect fittings. This unique single barb is available

in sizes to fit the 1/4” (6.4 mm), 5/16” (7.9 mm) and 3/8” (9.5

mm) ID tubing sizes and materials commonly used in disposable

and reusable medical equipment. Reinforced PVC, unreinforced

PVC and polyurethane tubingmaterials work well with this barb style.

The

900 SERIES

offers outstanding performance characteristics

when used with flexible tubing. Tubing is expanded from 8% to

17% above its nominal ID. This barb provides high flow efficiency

and excellent tensile strength. A hose clamp is recommended

for this series.

SINGLE BARB

MOLD PART LINE:

Placed where it

can’t affect critical

sealing surfaces.

Superior tool design

results in a sharp corner on

the barb, providing “bite”.

Tube is able to relax behind barb.

No mold parting line

on critical sealing surface.