15

X.Conclusion

Awell designed andproperly preparedpassive sampling systemhelps ensure

accurate, useful information is obtained from an air sampling project. In this

guide, we describe the components of the system, procedures for assembling

the system and preparing it for sampling, and the sampling procedure.

Cleaning system options and procedures for cleaning a used sampling train

and canister for certificationprior to a subsequent sampling also arepresent-

ed. The following section describes Restek products designed to help collect

and analyze air samples.

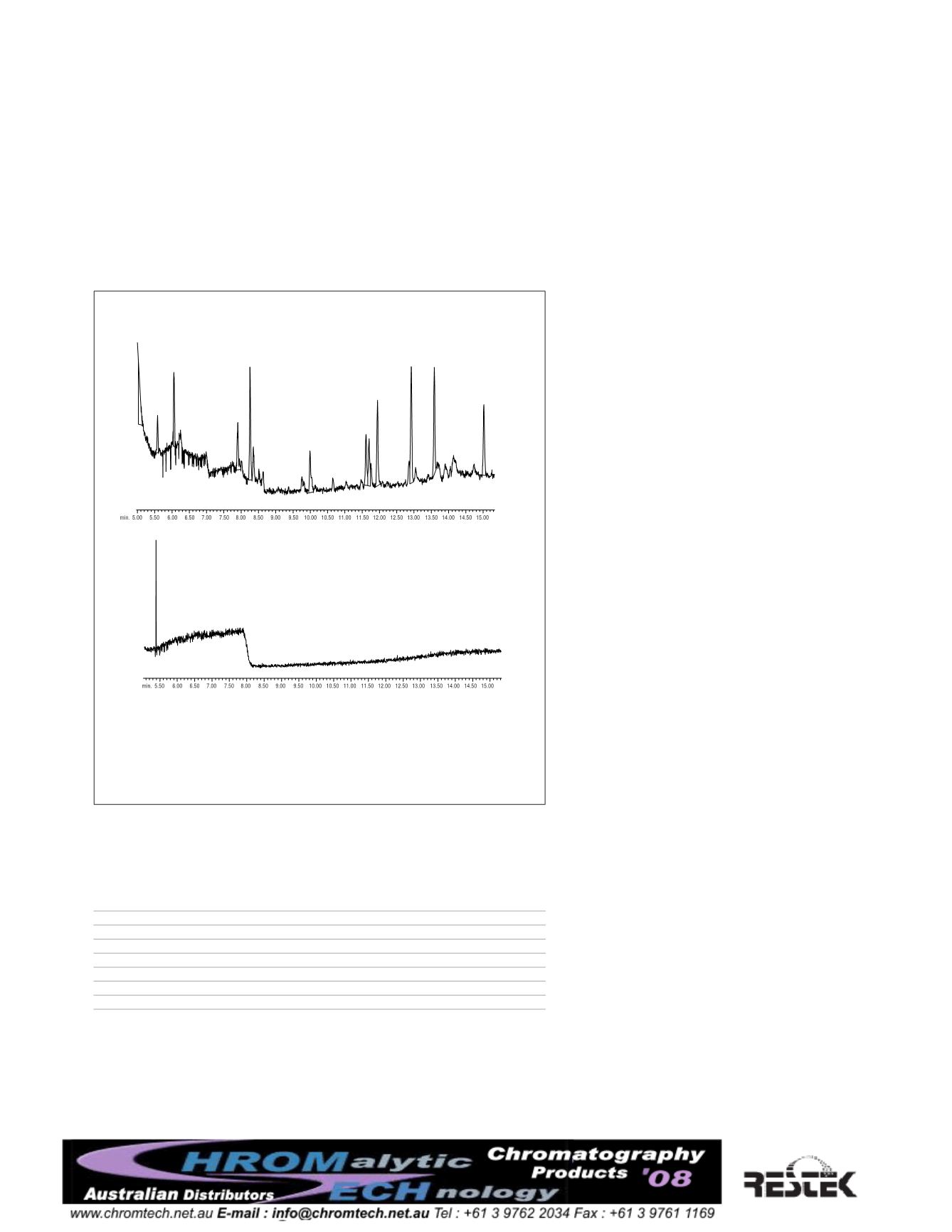

Dirtycan

Cleancan

Figure9

Aliquots froma canister beforeandafter cleaningwith

2 cyclesof humidifiedairwhileheated to200°C.

Rtx

®

-1 60m x 0.32mm ID x 1.0µm (cat.

#10157)

50°C (hold 1min) to 165°C@ 8°C/min.

to 220°C@ 15°C/min. (hold 5min.)

flow rate= 1.4mL/min.

Nutech 3550 Preconcentrator

conditions

sample= 300cc from canister

cryotrap= -160°C

desorb= 150°C

cryofocuser= -190°C

desorb= 150°C

MSD conditions

Instrument: HP5971GC/MSD

5minute solvent delay

scan range= 25-260amu

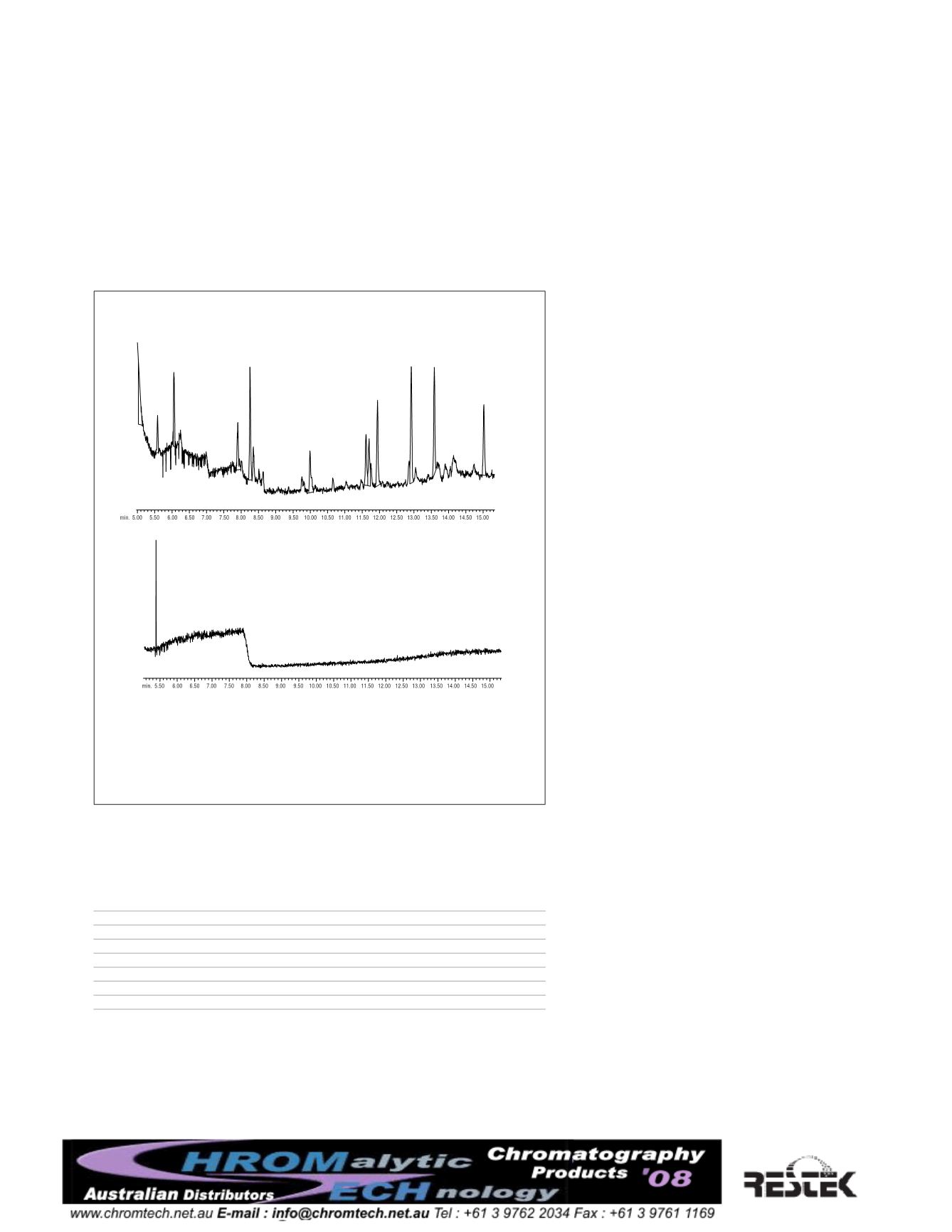

PressureConversionTable

Pressure

PSI

atm kg/cm

2

torr

kP

a

bar

inchesHg

PSI= 1

0.068

0.0703

51.713

6.8948

0.06895

2.0359

atm=

14.696

1

1.0332 760

101.32

1.0133

29.921

kg/cm

2

= 14.223

0.967

1

735.5

98.06

0.9806

28.958

torr=

0.0193

0.00132 0.00136

1

0.1330

0.00133

0.0394

kP

a

=

0.1450

0.00987 0.0102

7.52

1

0.0100

0.2962

bar=

14.5038

0.9869

1.0197 751.88 100

1

29.5300

inHg=

0.49612 0.0334

0.0345

25.400

3.376

0.03376

1

Multiply units in the left-most column by the conversion factors listed in the columns to the right.

e.g., 10PSI x 0.068= 0.68atm, 10 bar x 29.5300= 295.300 inches Hg