11

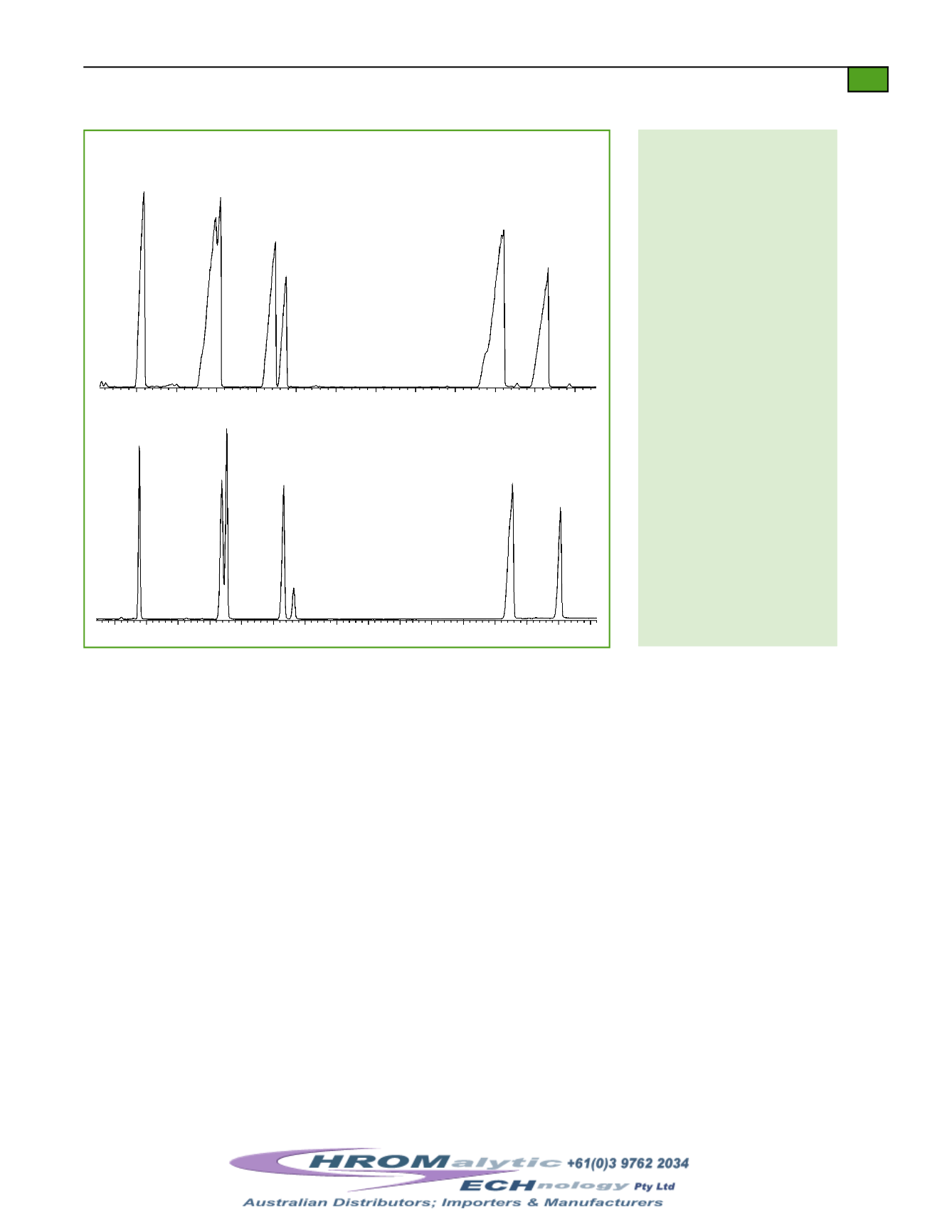

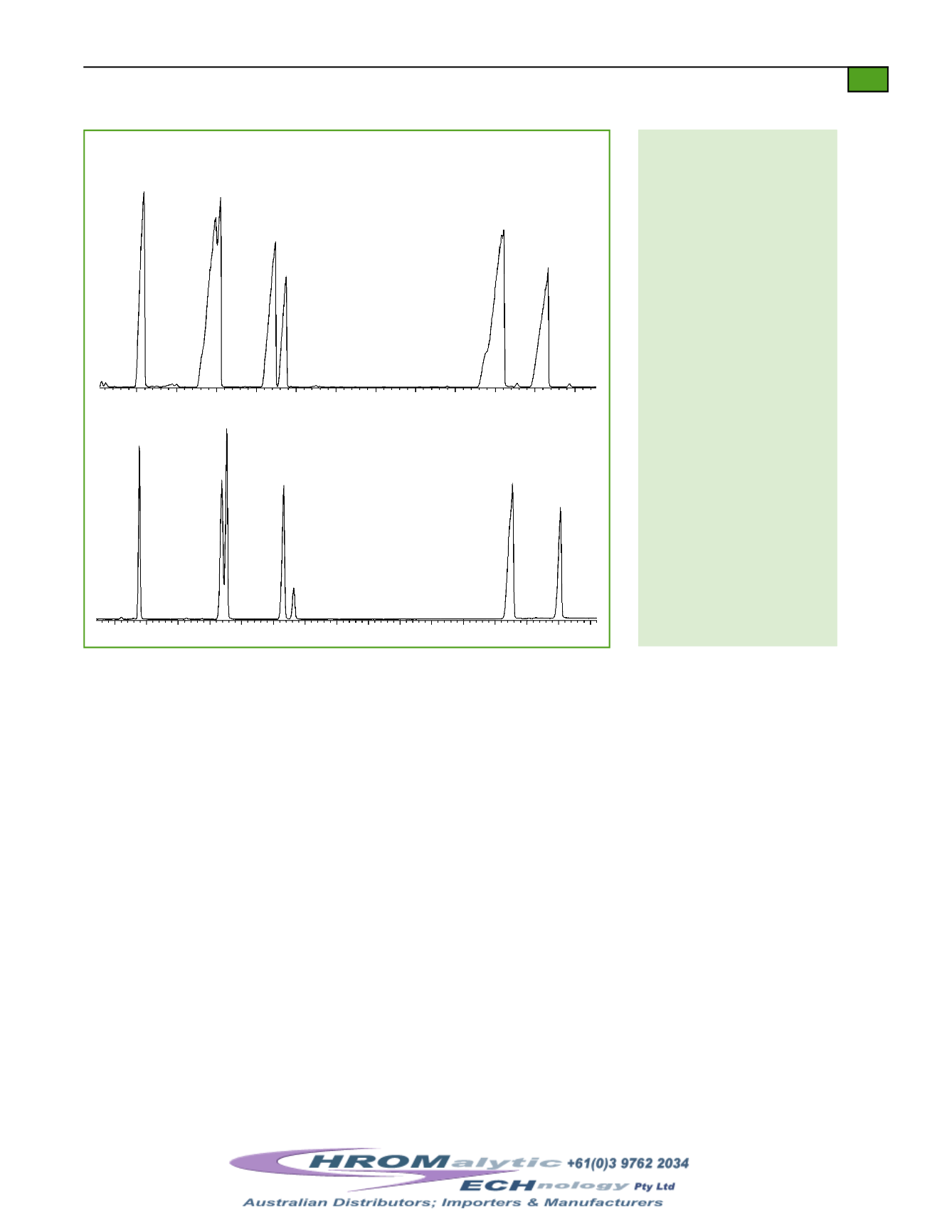

Figure4a&4b.

Avoidoverloadby selecting a columnwith theproper capacity.

1

2

3

4

5

6,7

8

1

2

3

4

5

6,7

8

Peak List for Fig. 4a& 4b

1. di-

n

-octyl phthalate

2. benzo(b)fluoranthene

3. benzo(k)fluoranthene

4. benzo(a)pyrene

5. perylene-d12

6. indeno(1,2,3-cd)pyrene

7. dibenz(a,h)anthracene

8. benzo(ghi)perylene

4a

Poor peak shape for a

0.25mm ID, 0.25µm

Rtx

®

-5SilMS column

4b

Excellent peak shape for a

0.25mm ID, 0.5µm

Rtx

®

-5SilMS column

to-separate analytes, sharing commonmass spectra andquantitation ions. Figure5 shows a

80ngper component injectionof the compounds listed inTable Iwith an analysis time under

30minutes. The expanded sections of the chromatogram show the excellent resolution that

canbe achievedwith theRtx

®

-5SilMS column.

In the past, theGC/MS systems used for semivolatile analysis didnot have the sensitivity for

split injections, so laboratorieswere limited to splitless injection.Newer systems such as the

Agilent 5973 and ion trapGC/MShave greatly improved sensitivity,which allow the use of

split injection

and stillmeet the detection limits requiredbymost semivolatilemethods.

Figure 6 shows the 20ngper component standard injected in splitmode using a 20:1 split ratio

on a 30m, 0.25mm ID, 0.25µmRtx

®

-5SilMS column. The lowbleed exhibitedby this

column is criticalwhenworkingwith thesemore sensitiveGC/MS systems.Abenefit of split

injection is narrower peakwidths for improved separations between closely eluting com-

pounds.Also, split injections usually result in less reactive compoundbreakdownbecause the

residence time in the injectionport ismuch shorter than in splitless injection.

If the sensitivityof an instrument allows for split injection, then column capacity is not nearly

the issue it is for splitless injection. Figure 7 shows a 160ng-per-component standard injected

under the same conditions as shown inFigure 6.Acolumnwith a thinner film canbe used

because the concentration reaching the column is reducedby20-fold. The analytical system

using split injectionwill be able tohandlehigher concentrations of contaminants andpossibly

stay calibrated longer, but therewill be a sacrifice inmethoddetection limits (MDLs).

Therefore, it is important to ensure that theMDLs specified in a particularmethod still canbe

met if split injection is used.

18.5 16.0 16.5 17.0 17.5 18.0 18.5 19.0 19.5 20.0 20.5

min.

18

19

20

21

22

23

24

min.

Conditions for Fig. 4a

30m, 0.25mm ID, 0.5µmRtx

®

-5SilMS

(cat.#12738)

160ng splitless injectionof CLP

standard;

GC:

HP/Agilent 6890w/ 5973

mass selective detector, scan range 35-

550AMU;

Ovenprogram:

40°C(hold2

min.) to290°C@20°C/min. (hold0

min.) to303°C@2°C/min. (hold0min.)

to 330°C@ 6°C/min. (hold 1min.);

Carrier gas:

He@1.0mL/min. constant

flow;

Inj. temp.:

300°C;

Det. temp.:

280°C

Conditions for Fig. 4b

30m, 0.25mm ID, 0.25µmRtx

®

-5SilMS

(cat.#12723)

unknown concentration (>160ng)

splitless injectionof CLP standard;

GC:

HP/Agilent 6890w/ 5973mass

selective detector, scan range 35-550

AMU;

Ovenprogram:

40°C (hold2min.)

to 245°C@ 25°C/min. (hold 0 min.) to

330°C@6°C/min. (hold5min.);

Carrier

gas:

He@ 1.0mL/min. constant flow;

Inj. temp.:

300°C;

Det. temp.:

280°C

Website :

E-mail :

TelNo : 03 9762 2034 . . . inAUSTRALIA