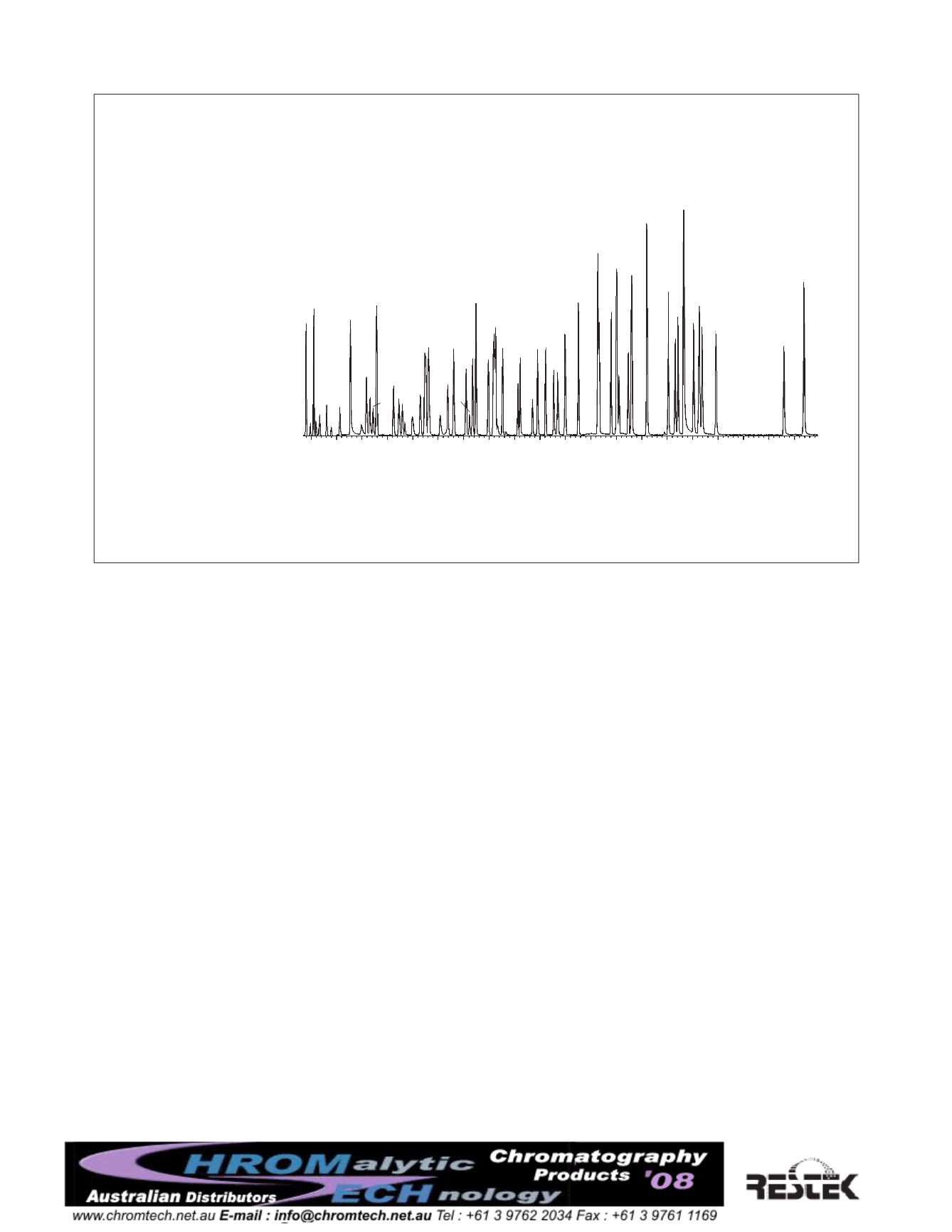

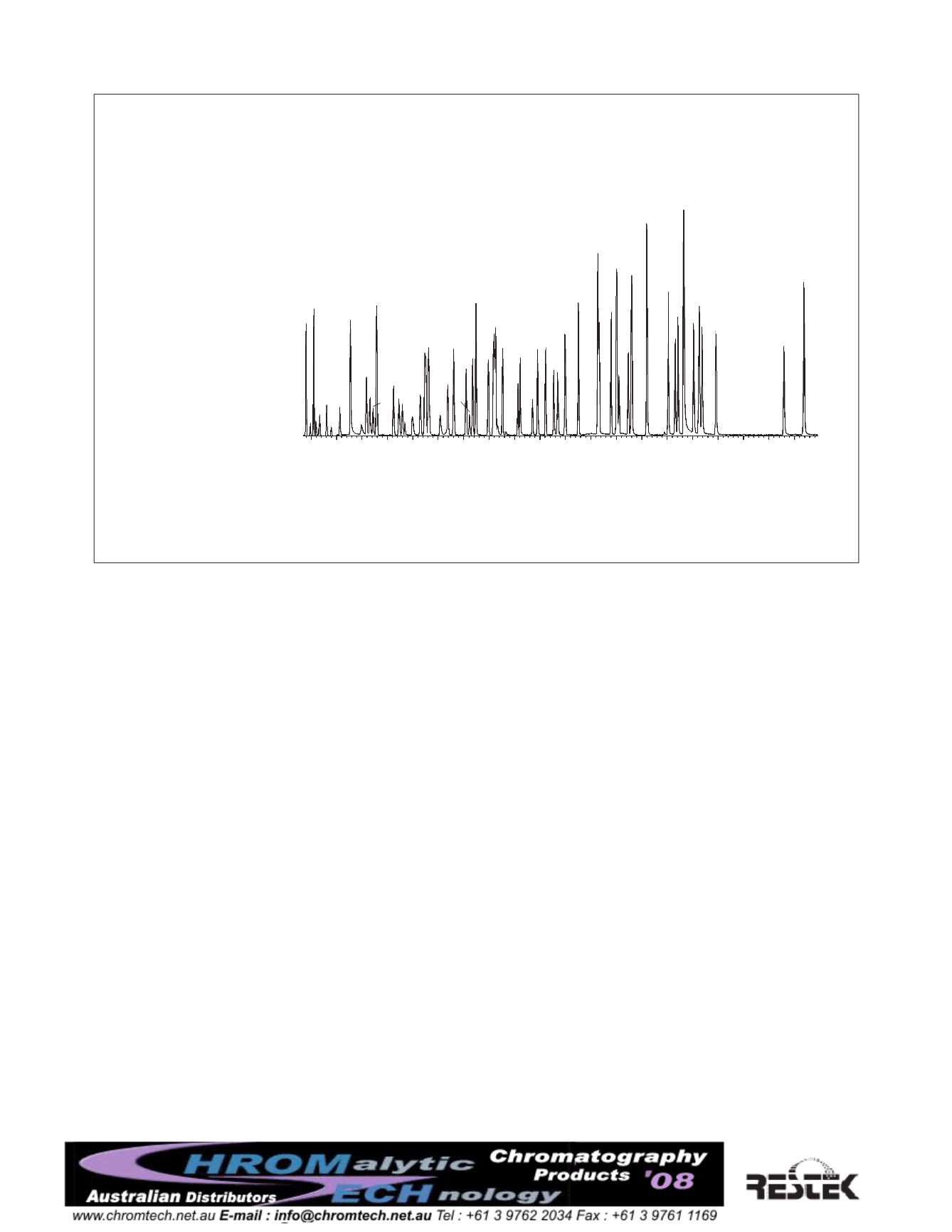

Figure 7

TLC spectrum for a TO-14/TO-15 ambient air analysis.

11

tor to each “unknown” analyte peak area to get the reporting limit concentra-

tion of the “unknown” in the analysis (typically in ppbv). If you have diluted

the canister to get a positive pressure, however, you must apply the dilution

factor to the concentration values. This is done by multiplying the reporting

limit by the dilution factor.

VII. Cleaning the Passive Sampling Train

The cleanliness of the sampling train is critical to collecting accurately repre-

sentative samples. Practices followed for cleaning passive sampling equipment

between uses range from purging the sampling pathway with humidified

nitrogen or air for many hours to heating the pathway during a purge to dis-

assembling each component, sonicating the pieces in solvent, and oven baking

the pieces prior to re-assembly. The most suitable mode of cleaning depends

on the concentrations of analytes of interest, and contaminants, in the previ-

ous sample collected.

The particle filter must be thoroughly cleaned between uses. Disassemble the

filter, then remove the larger particles from the frit by blowing particle-free

nitrogen through the frit from the outlet surface toward the inlet surface. After

the larger particles are removed sonicate or rinse the filter parts in methanol,

then bake the parts in an oven at 130°C to remove any residual organic vapors.

The critical orifice and flow controller can be cleaned in either of two ways.

The first method is to disassemble the flow controller and clean all the metal

parts with methanol. This will remove any high boiling compounds that have

condensed onto the wetted areas of the controller. Heat the cleaned parts in an

oven at 130°C to remove residual organic vapors. Do not sonicate in solvent or

bake any of the non-metallic parts, such as O-rings; they will be damaged dur-

ing these steps. Do not rinse the vacuum gauge with methanol. The vacuum

gauge may be heated, but do not exceed 80°C; higher temperatures will dam-

age the face and the laminated safety glass lens. Heating to 80°C will not affect

the mechanical operation of the spiral bourdon tube in the vacuum gauge.

Rtx

®

-1 60m, 0.32mm ID, 1.0µm (cat.# 10157).

Sample:

200mL of 10ppbv TO-15 standard (cat.# 34436), injected into TO-Can

™

canister and humidified to 70% RH.

Concentrator:

Nutech 3550 Preconcentrator

200mL of sample concentrated at -160°C, thermally desorbed at 150°C, and cryofocused at -185°C.

Oven temp.:

30°C (hold 4 min.) to 175°C @ 9°C/min. to 220°C @ 40°C/min.

Carrier gas:

helium @ 1.2mL/min.

Det.:

Agilent 5971 MS

Scan range:

35-265amu

4 5

6

7 8

9

10 11

12

13 14 15 16 17 18 19 20 21 22 23 min.

1

3

4

5

6

7

8

9/10

11

12

13

14

15

16

17

18

19

20

21

22/23

24

25

26

27

28

29

30

31

32

33

34

35/36

37

38

39

40

41 42

43 44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

BFB

GC_EV00379

2

1. dichlorofluoromethane

2. chloromethane

3. dichlorotetrafluoroethane

4. vinyl chloride

5. 1,3-butadiene

6. bromomethane

7. chloroethane

8. bromoethene

9. acetone

10. trichlorofluoromethane

11. isopropyl alcohol

12. 1,1-dichloroethene

13. methylene chloride

14. 3-chloropropene

15. carbon disulfide

16. Freon

®

TF

17.

trans

-1,2-dichloroethene

18. 1,1-dichloroethane

19. methyl

tert

-butyl ether

20. methyl ethyl ketone

21.

cis

-1,2-dichloroethene

22. bromochloromethane (IS)

23.

n

-hexane

24. chloroform

25. tetrahydrofuran

26. 1,2-dichloroethane

27. 1,1,1-trichloroethane

28. benzene

29. carbon tetrachloride

30. cyclohexane

31. 1,4-difluorobenzene (IS)

32. 1,2-dichloropropane

33. bromodichloromethane

34. trichloroethene

35. 1,4-dioxane

36. 2,2,4-trimethylpentane

37.

n

-heptane

38.

cis

-1,3-dichloropropene

39. methyl isobutyl ketone

40.

trans

-1,3-dichloropropene

41. 1,1,2-trichloroethane

42. toluene

43. methyl butyl ketone

44. dibromochloromethane

45. 1,2-dibromoethane

46. tetrachloroethene

47. chlorobenzene-d5 (IS)

48. chlorobenzene

49. ethylbenzene

50.

m

/

p

-xylene

51. bromoform

52. styrene

53. 1,1,2,2-tetrachloroethane

54.

o

-xylene

55. 2-chlorotoluene

56. 4-ethyltoluene

57. 1,3,5-trimethylbenzene

58. 1,2,4-trimethylbenzene

59. 1,3-dichlorobenzene

60. 1,4-dichlorobenzene

61. 1,2-dichlorobenzene

62. 1,2,4-trichlorobenzene

63. hexachlorobutadiene